brief Introduction:

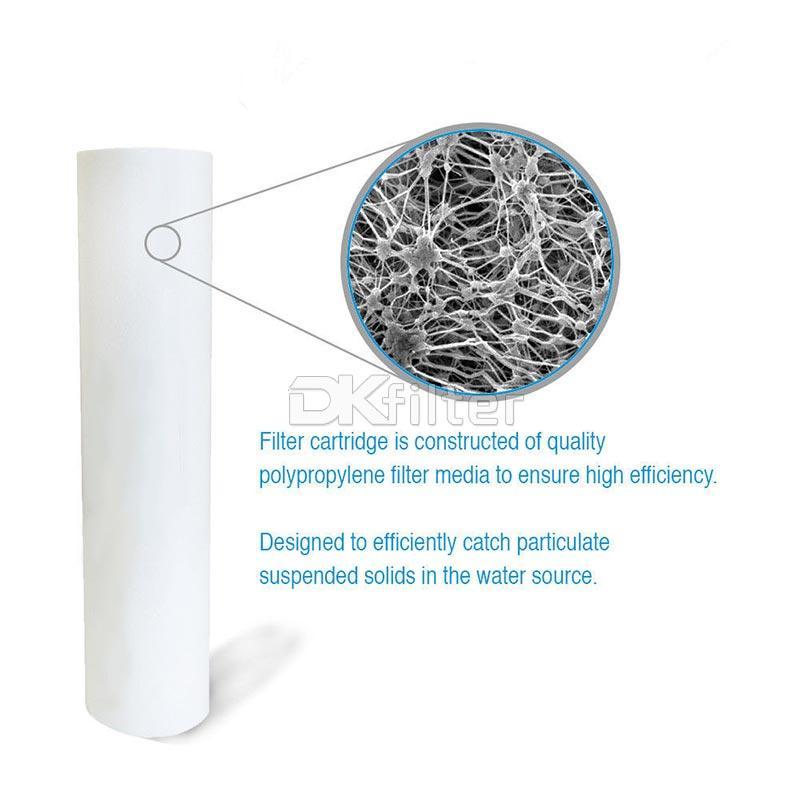

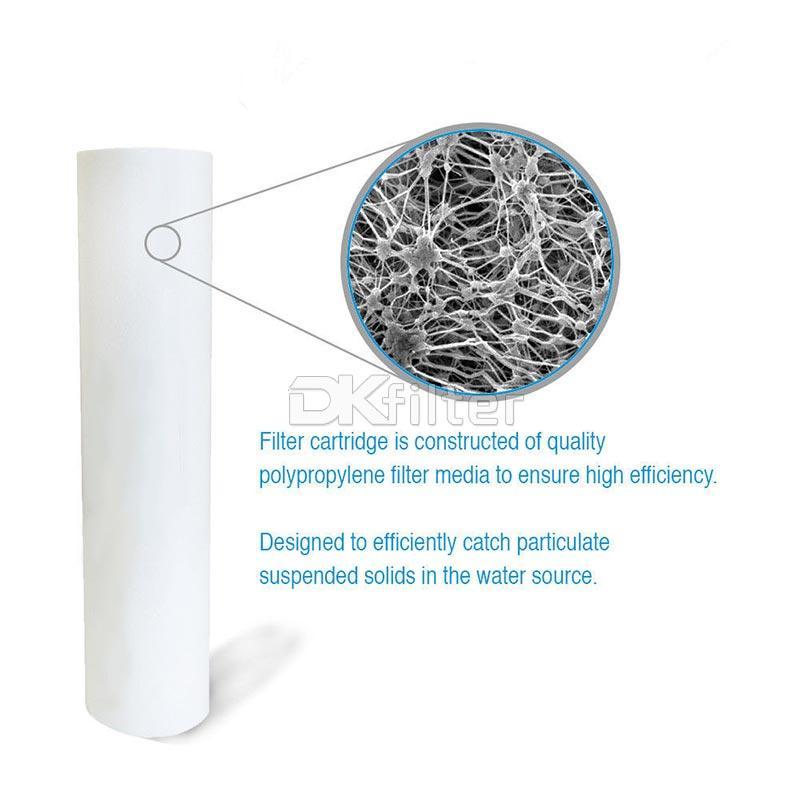

Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge is used to clean and filter water fluids and effectively remove impurities such as tiny particles and bacteria in the water fluids. The filtration efficiency is as high as 99.8%, ensuring the original quality attributes of the water fluids. It is a high-efficiency microporous pleated water filter type.

Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge manufacturing materials are made of high-quality, safe and environmentally friendly filter membranes, and imported non-woven fabrics or mesh fabrics are used as the support layer, with full batch material traceability. The filter housing, center rod, and end caps adopt hot-melt welding technology without using any adhesives, additives, or lubricants, and without any fiber shedding. The production process is environmentally friendly, pollution-free and leak-free. 100% integrity tested during production, manufactured, rinsed, tested and packaged in a clean room.

Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge structure adopts multi-layer stepped folding w-pleated corrugated shape UP media technology design to achieve the maximum processing capacity of pollutants and excellent pollutant absorption capacity and interception efficiency, ensuring that the required filtration cleaning standards are met. The filter material complies with FDA requirements, has strong mechanical strength and extensive chemical resistance, and is suitable for various filtration scenarios.It can meet many key industries such as water treatment, food and beverage, pharmaceutical filtration, solvents, semiconductors, cosmetics, bottled water, etc.

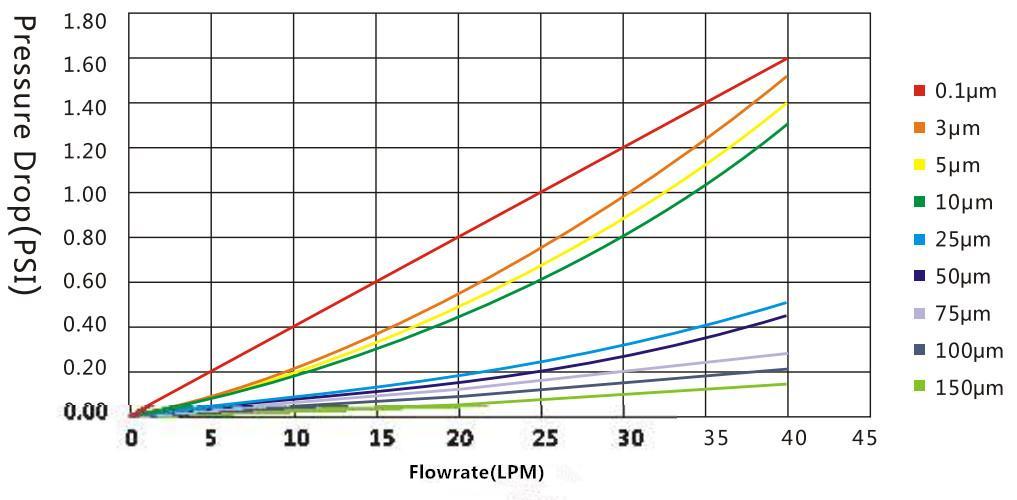

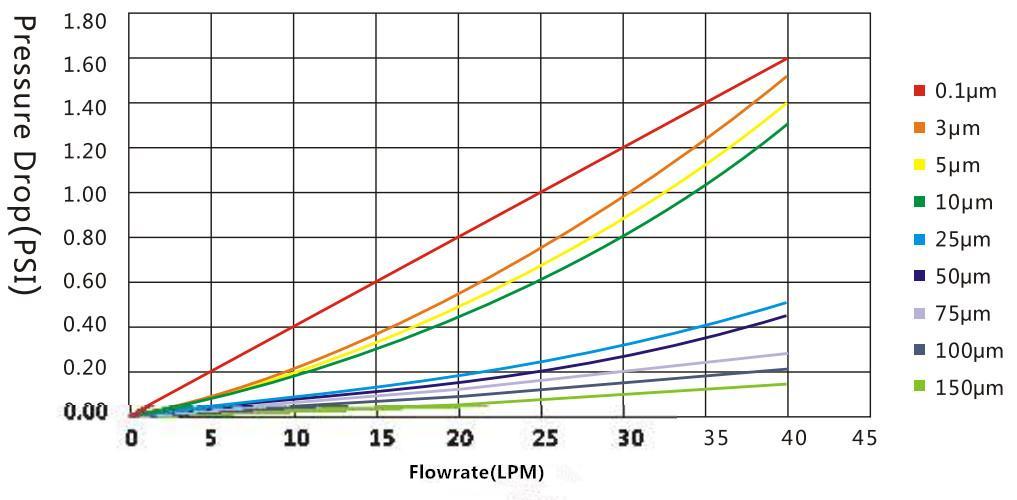

The flow characteristics of PP material are as follows:

....

Technical specifications:

• Filter Material: Pleated Fiberglass, Pleated Deep Polypropylene (PP), MBPP

• Maximum pressure drop: pleated fiberglass--4.0bar, pleated deep polypropylene (PP)--3.4bar, MBPP--1.03bar

• Maximum temperature: wrinkled fiberglass--121℃, deeply wrinkled polypropylene (PP)--82℃, MBPP 65℃

• Support/Diversion Layer: Polypropylene (PP)

• Sealing material: EPDM, BNR

• End cap: fiberglass reinforced polypropylene

• Center pole: polypropylene

• Filter element surface: PP melt-blown, melt-blown fine lines, melt-blown grooves, melt-blown embossing

• Gasket: silicone rubber, ethylene propylene rubber, nitrile rubber, fluorine rubber

• Recommended maximum filtered water flow rate: 660L/min for 20-inch filter, 1300L/min for 40-inch filter, 1900L/min for 60-inch filter

• Filtration precision: 0.1μm, 0.22μm, 0.45μm, 1μm, 3μm, 5μm, 10μm, 20μm, 50μm.

Filter Material

....

Advatage:

• Made of PP microfiber with high filtration accuracy.

• High-quality filter media combined with internal multi-layered pleated depth filtration.

• High-quality filter material and hot-melt bonding process, high cleanliness, no adhesive added, no pollution to water quality.

• Deep groove folding design increases the filtration area and the pressure drop is significantly lower than ordinary filter elements

• Large diameter design increases the anti-fouling properties of the filter element, prolongs service life and reduces usage costs.

• Convenient handle design, easy to replace and portable.

• The surface fiber structure is strengthened to prevent the filter material fibers from falling off.

• High-strength rigid external support enhances the filter element's ability to withstand pressure, making it ideal for harsh conditions and demanding applications with repeated cleaning.

• Fully sealed interface design reduces the risk of side flow and ensures the tightness and reliability of filtration.

• The filter material complies with FDA requirements, has excellent chemical compatibility, and is suitable for filtering strong acids, strong bases and organic solvents.

Quality Assurance:

ISO 16889------Multi-pass Performance Testing

ISO 3968------Pressure Drop vs. Flow Rate

ISO 3724------Flow Fatigue Characteristics

ISO 2943------Material Compatibility with Fluids

ISO 2942------Fabrication & Integrity Test

ISO 2941------Collapse & Burst Resistant

Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge

Pleated Polypropylene(PP) Water Treatment RO Filter Cartridge

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)