Description:

LYC-B high-precision oil purifier is divided according to the structural form.It consists of a gear pump,filter,safety valve,oil return valve,drain nozzle,filter bed,front bracket,rear bracket.An instrument composed of chassis,tie rods,couplings and electric motors.

Features:

The oil filter consists of a motor-driven gear pump dedicated,low noise,strong self-absorption capacity,smooth running characteristics.

High-pressure pipe with overflow protection devices, can effectively protect the safety of the hydraulic system.

Thermal relay protection to prevent motor damage caused by motor overload.

Suction port coarse filter to protect the pump and extend the life of the main filter.

After the pump has two fine filter, so the oil quickly reach high cleanliness.

Fine filter according to the different needs of users,choose a different precision,achieve the desired results.

Oil filter housing with quick open structure,without any tools will be able to quickly open the cover quickly,replace the filter.Equipped with a pressure gauge on the panel,while working continuously indicate the degree of contamination and the health system filter.

Applications:

●Filtration of hydraulic lubrication system when refueling

●Hydraulic lubrication system bypass filters at work

●Hydraulic lubrication system put into operation before the loop filter

●Hydraulic oil pump lubrication system does not filter out the pump through the device itself.

(Note:The machine isn’t suitable for fuel and other flammable media)

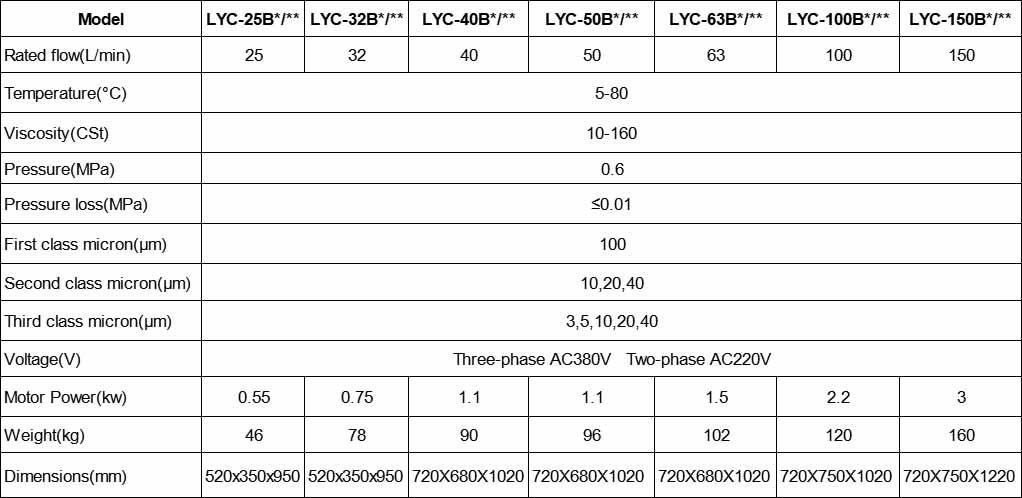

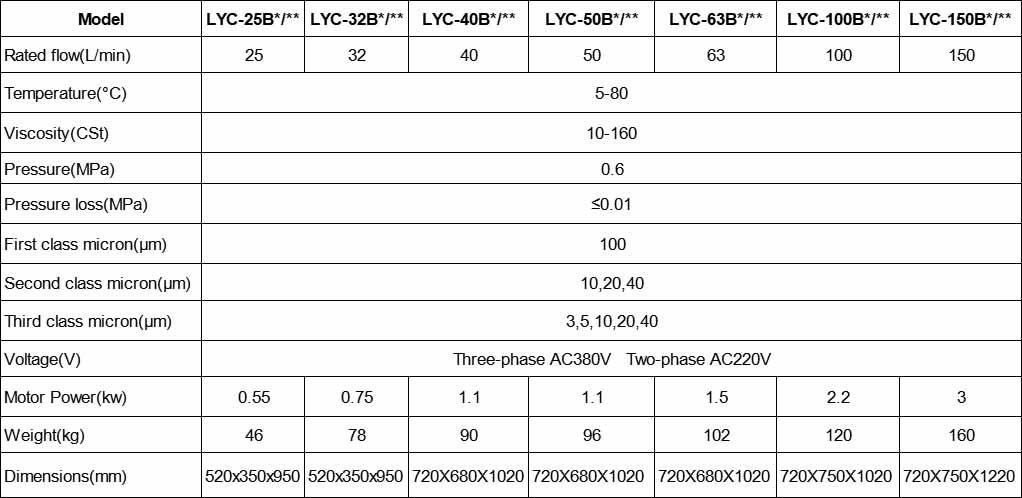

Technical parameters:

Note:

* Secondary precision filter accuracy, such as 003 means 3 um

** The applicable media: generally hydraulic oil,BH: water, glycol,V: phosphate ester hydraulic fluids

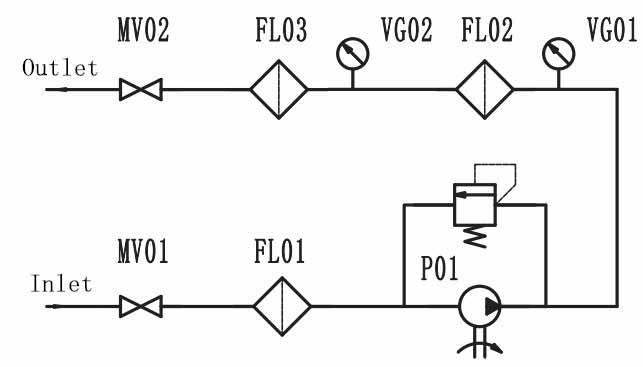

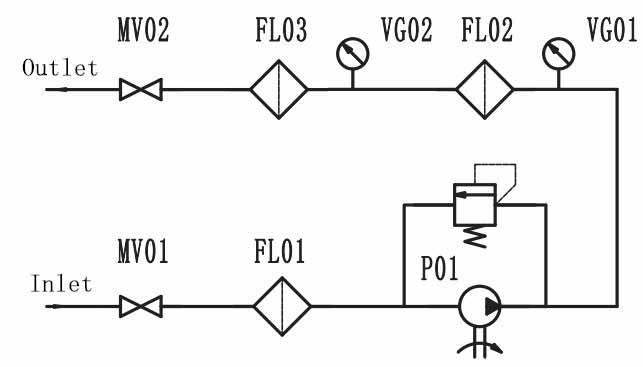

Hydraulic schematics:

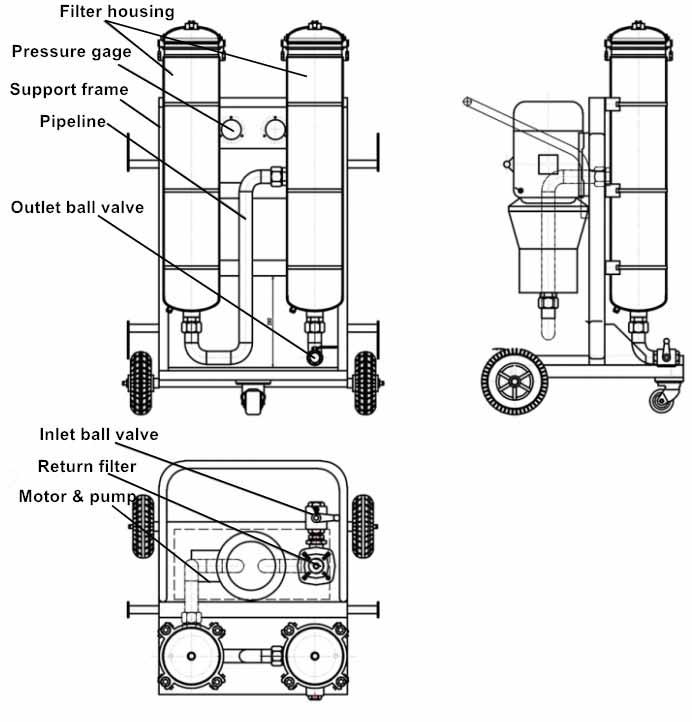

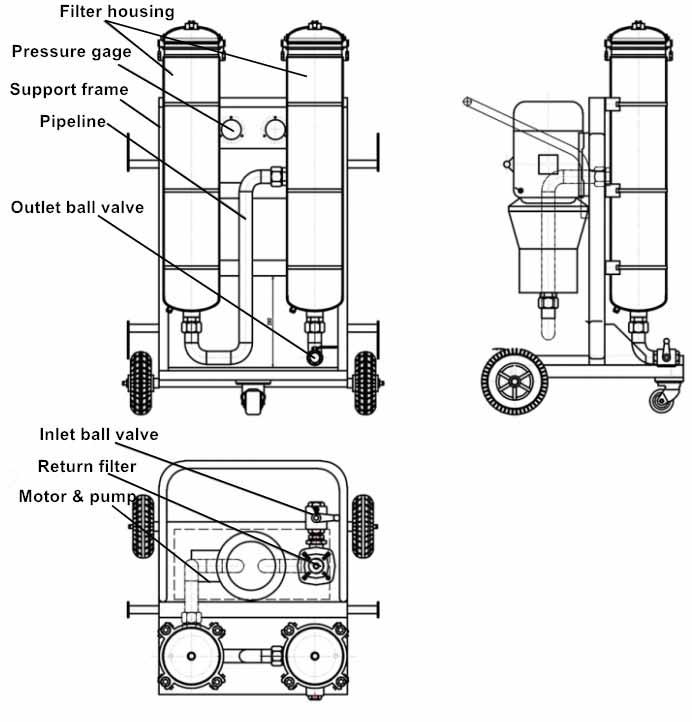

Outside shape & structure:

Test standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Operating procedures:

1).Connect the power.

2).The inlet and outlet pipe connected to an external source of oil, and import and export valve open.

3).Jog switch the green button, observe steering pump, if turning right, should be immediately shut down, change the power supply phase sequence.

4).Green button start switch, pump system rotation on the oil filter.

5).After the system starts, put the valve plug micro-fine filter at the top of the loose, let the system gas emissions,after the drain plug and tighten gas.

6).After the oil out of the normal,you can filter the refueling work.

7).Off: out of the suction pipe,drain the oil;press the red button,the motor stops;closed inlet and outlet valves;coiled up and clean out the tubing,to prepare for the next use.

Filter cleaning and change:

After working for some time when the oil filter, oil filter pressure oil system is correspondingly increased, resulting in different elements of their performance impact, particularly on the filter cartridge to produce maximum accuracy, and even the filter is damaged, the main reason filter differential pressure is increased. Thus, when working for some time after the oil filter, the filter requires cleaning and replacement.

Specific cleaning and replacement of the following methods:

1).Clean:(Just before the oil filter on the pump)

2).Cleaning cycle:One week of continuous work Purifier(About150hours)

Clean way:

a.Unscrew the nut on the suction filter flange, remove the flange, and then remove the filter.

b.Clean filter:When cleaning the filter, with gasoline soak for about half an hour later, with a brush to remove impurities.

Change:

1).Change Condition:Pre-filter cartridge when the gauge indicates the difference is more than two-0.25MPa, the need to replace the pre-filter cartridge. When the secondary pressure gauge is greater than 0.25MPa, the need to replace the fine filter cartridges.

2).The way of changing the filter:Loosen the clamp at the top of the filter assembly, remove the cover, remove and replace the filter.

Notice:

a.The oil filter does not filter gasoline and other flammable liquids.

b.For this oil filter, a filter can achieve good results, if you want to achieve higher filtering accuracy, loop filter 5-8 times, you can achieve the best filtering effect.

c.If the oil tank (or tanks) of oil is dirty and could have a big obstacle in the suction port should be installed on a large mesh strainer protection.

d.Suction use flow lines should be kept clean.

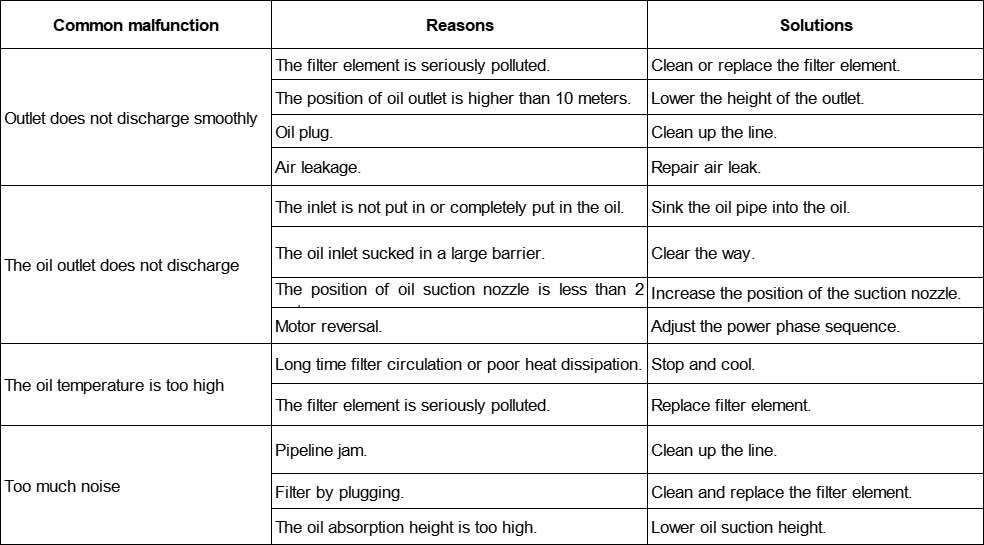

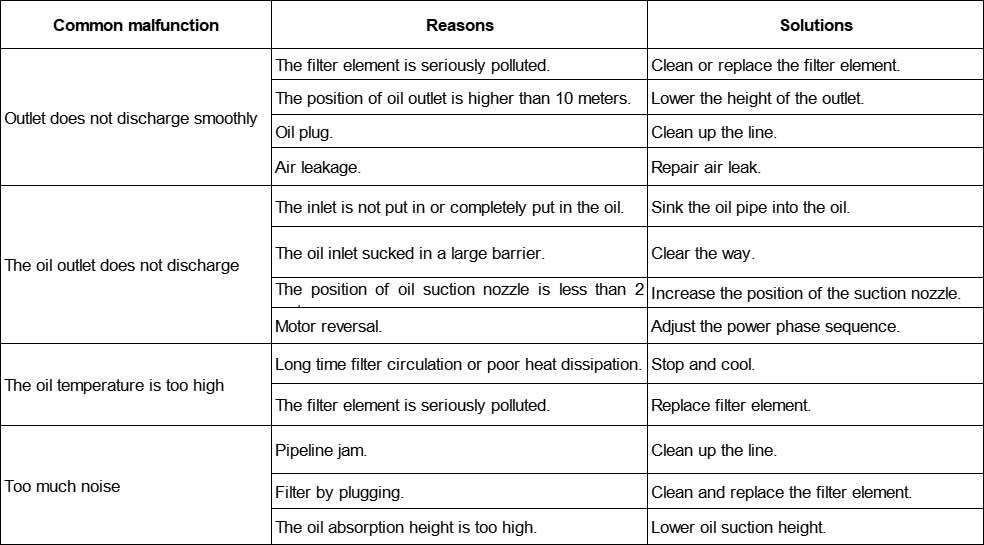

Common causes of failure and Remedy:

LYC-B Series high-precision oil purifier

LYC-B Series high-precision oil purifier

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)