Description:

ZlYC Series High Effective Vacuum Oil Purifier is used to remove water in various states from the oil,and can also remove air and various volatile substances from the oil.

Its operation principle is that different liquids have different saturation vapor pressure.At a temperature of 70 ℃,and water at about 30000Pa pressure begins to boil,and the oil in the low pressure of 5Pa to boiling.At the same temperature,oil saturation vapor pressure is much lower than water.Therefore,the oil in the liquid by vacuum pressure lowered to below the saturation vapor pressure of water,the oil in water will dramatic gasification,in the form of vapor from the oil spill.

By vacuum suction,fluid entering from the top through the vacuum tank and nozzle spray down,the oil in the water and is vaporized in a vacuum chamber vacuum extraction, in addition to oil after water is discharged from the bottom.In the middle of the vacuum chamber filled with a lipophilic material,the shower down the oil filler dispersed in the surface film formed by a thin,to increase the gas-liquid two-phase interface area,and the oil in the vapor space to extend the residence time.

The effect of ZlYC Series High Effective Vacuum Oil Purifier removing water is mainly related with the work of the vacuum and the oil temperature.The lower the degree of vacuum is,the higher the temperature is, the better the effect of water addition.Oil temperature is usually around 60 ℃,the temperature is too high will accelerate the oxidation of oil.For the hydraulic oil,the degree of vacuum is generally 600 ~ 700Pa,the moisture content to make the oil less than 100ppm.For the transformer insulating oil,the higher the degree of vacuum can be used; the water content can be reduced to 10ppm.

Applications

● Oil purifier of turbine oil and transformer

● In addition to water, hydraulic and lubricating oil filter impurities

● Comprehensively improve the cleanliness of hydraulic lubrication system

● Various types of oil regeneration purifier

● turbine oil

● hydraulic oil

● Lubricants

● insulating oil

● transformer oil

● capacitor oil

● compressor oil

Product Performance

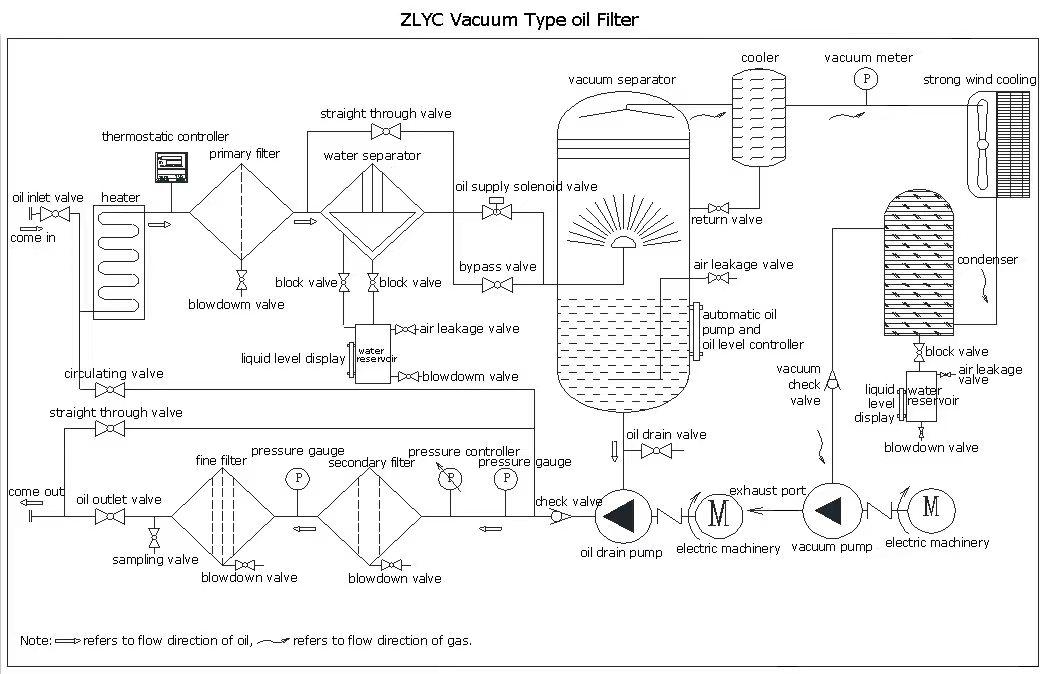

1. Vacuum System:

By vacuum tank, vacuum pumps, condensate tanks, fluid tanks, air-filling system.

Optimized structure design, greatly increasing the surface area of the oil in the vacuum system, and maximizing oil travel in a vacuum system. The oil in the water and gas are fully overflowed. This machine adopts advanced defaming system so oil filter at work will not appear similar products widespread phenomenon of injection.

2.Filtration system:

Using three filter, coarse filter inlet to protect the pump and extend the life of the main filter. After the pump has two fine filter, so the oil quickly reach high cleanliness. Using special gradient filter pore glass fiber material that can be layered filter particles of different size, which greatly improved the life of the filter. The filter has a perfect structure, which can effectively reduce the surface velocity filter, access to stable filtration accuracy.

3. Heating system:

Segmented gradual heating surface heat load is small 1.0W / cm2, the oil does not overheat causing deterioration. Oil temperature can be adjusted at 0 ~ 100 ℃, automatic control, and a protective device, the amount of oil is too low today automatically stop working, to avoid damage caused by dry heater.

4. Automatic control system:

The machine uses the frequency, level transmitters, temperature sensors, vacuum degree sensing instrument, such as a series of automatic control instruments of various information acquisition device run by the central processor for processing, automatic control of the whole equipment run and monitor the operational status of equipment. The unit comes with a variety of protective devices (overload, overvoltage protection, phase sequence protection, abnormal operation shutdown protection) to ensure safe operation of equipment.5.

The whole structure:

Machine integration bridge structure, reducing the volume. Holistic removable tank, ensure that the ground without oil operations, reduce environmental pollution. There are mobile, fixed, fully enclosed, vehicle type, and so many models to choose from.

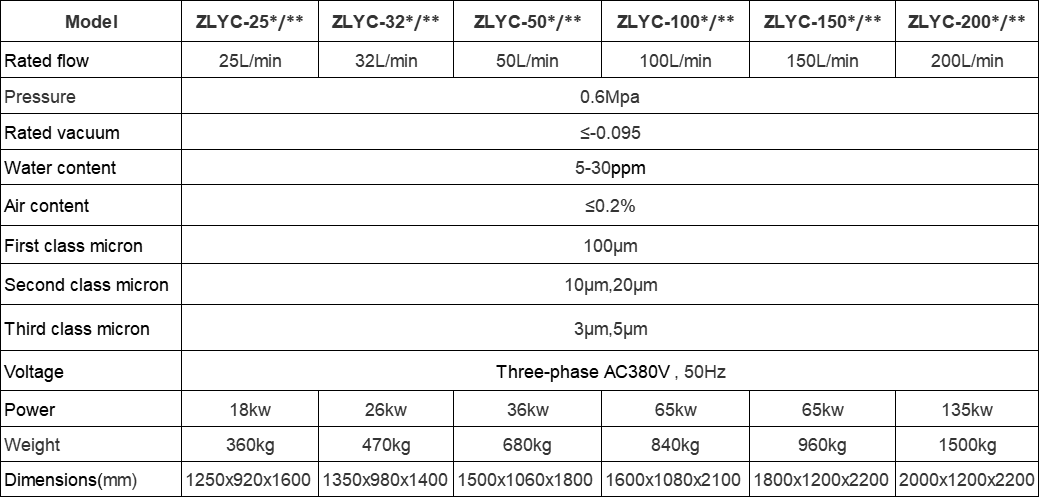

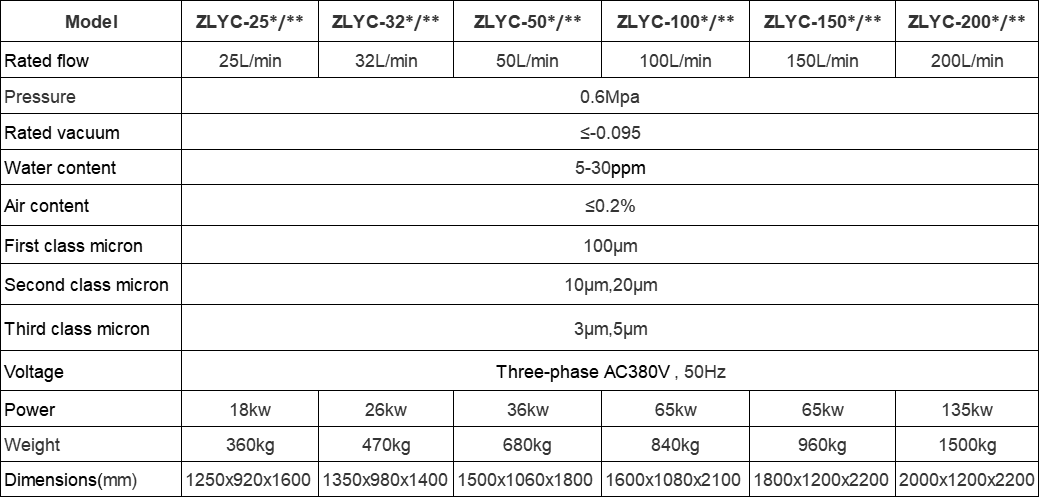

Technical parameters:

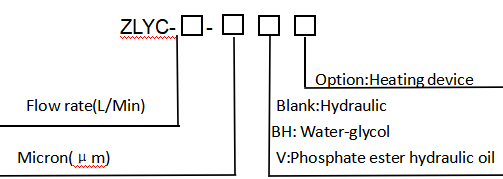

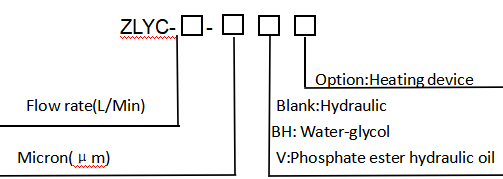

Model code:

Efficient vacuum oil major functions:

● Dehydration

● Degassing

● Removal of mechanical impurities and reproducing apparatus can be connected in parallel:

● Acid removal

● Decolorization

● Improve the insulation strength

1. Clear Water

Oil free water and dissolved water by reducing the lubricity, oxidation and formation of the acid leaving the oil deterioration, even if the non-aqueous fluid is exposed to high-temperature oxidation and the formation of organic acids is not easy. The presence of an organic acid compounds cause corrosion. Water accelerate thermal degradation of the oil to produce a pellet or a carbonaceous material. The presence of water also causes the formation of oil polymerization macromolecules. Polymerization of the resulting change in viscosity, clogging of the orifice is generated on the system component wear and harmful in terms of solids. SLYJ efficient vacuum oil purifier can remove 100% of free water and more than 95% of dissolved water.

2. Clear the Air

Efficient vacuum oil purifier can remove 100% of free air and up to 75% of dissolved air, the air at the time the oil is cleared through the vacuum tank. Other gases depending on the cycle time is reduced to trace amounts.

3. Clear the solid particles

In order to remove the suspended particulate matter, SLYJ efficient vacuum oil filter to filter out caused by three bearings, pumps and valves in abrasive wear particles. It is also clear that may have accumulated between the valve and the valve sleeve gap and cause electro-hydraulic servo valves instability gripping and silt. In the insulating oil, the level of this filter prevents electrical caused by charged particles bypass effect breakdown.

ZlYC Series High Effective Vacuum Oil Purifier

ZlYC Series High Effective Vacuum Oil Purifier

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)