RFA-400×10L-Y/C Brief Introduction:

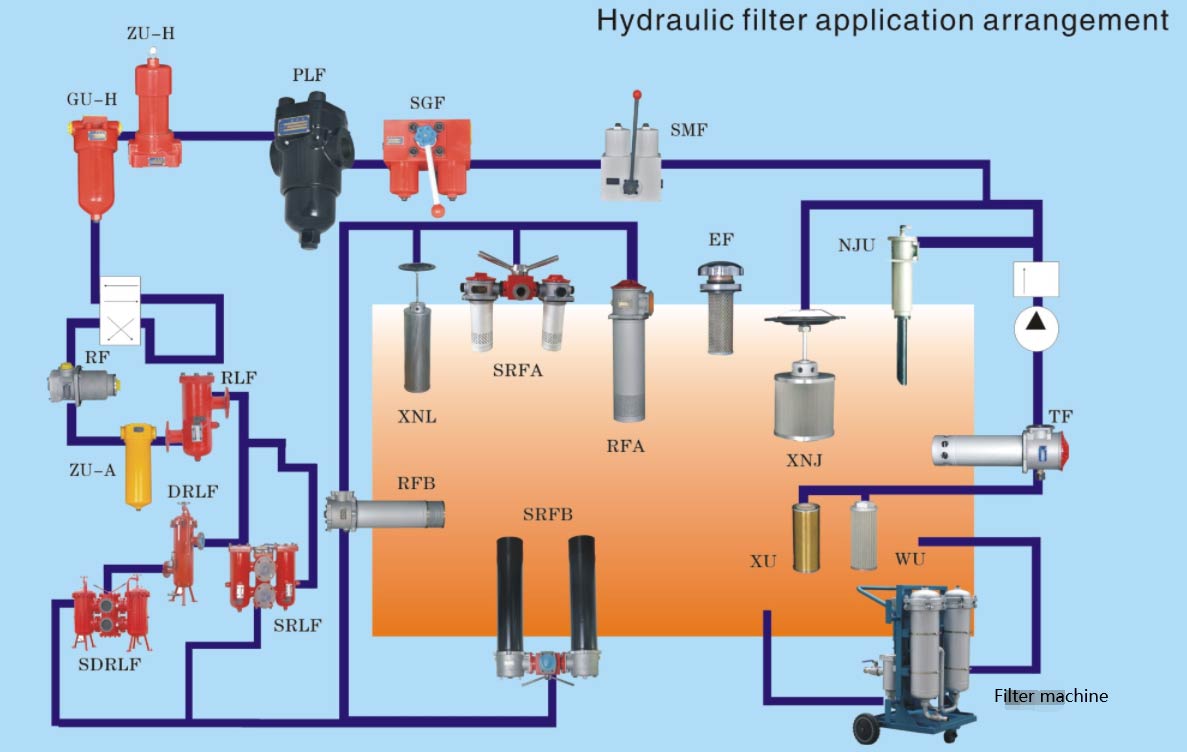

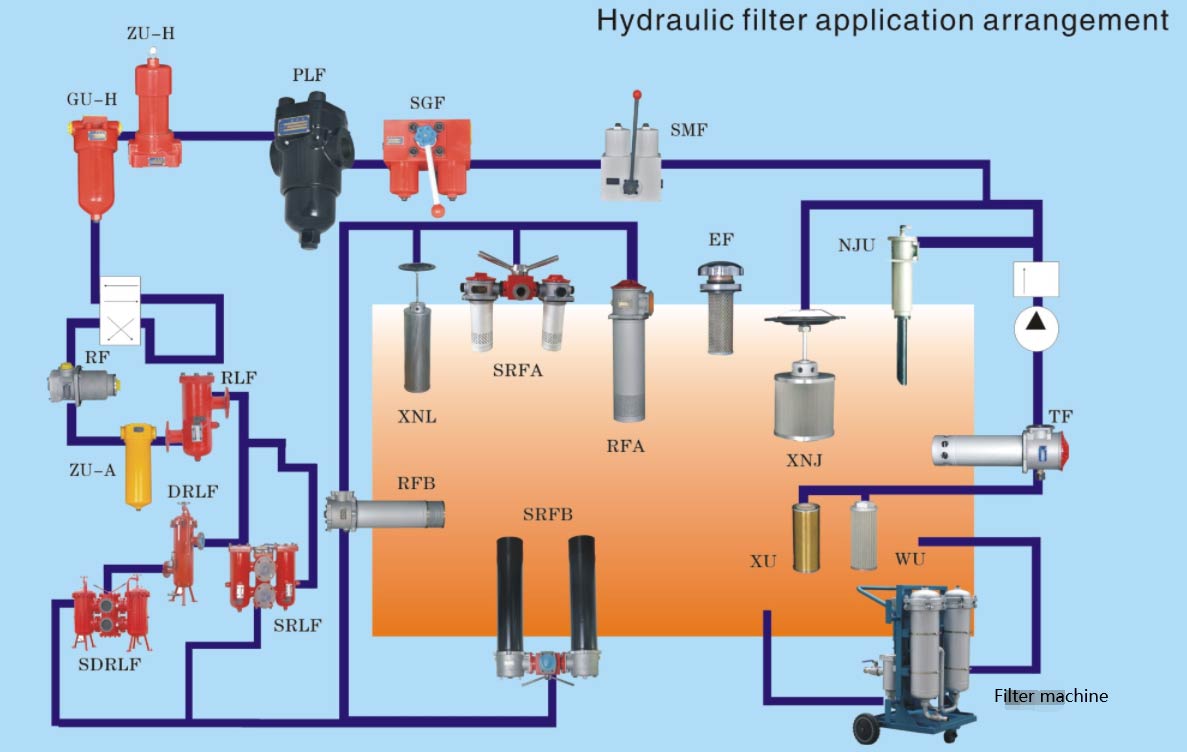

DKFILTER makes kinds of filter housing,and the hydraulic oil filter housing RFA-400×10L-Y/C is used to filter the return oil in the hydraulic system to filter out the metal particles produced by the wear and tear of the components in the hydraulic system and the rubber impurities of the seals and other pollutants, so as to keep the oil flowing back into the oil tank clean.

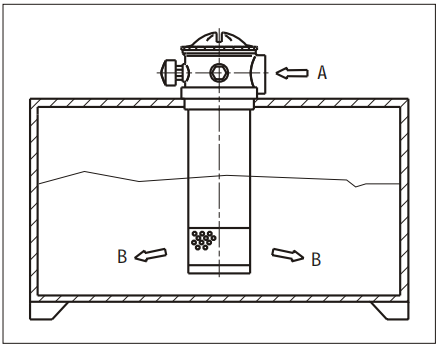

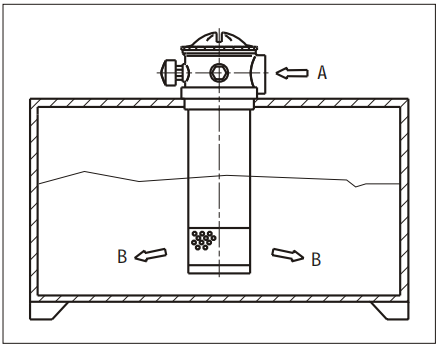

RFA-400×10L-Y/C is installed on the top of the fuel tank,and the cylinder part is immersed in the fuel tank,and equipped with bypass valve,diffuser,filter element pollution blockage signaler and other devices.It has the characteristics of compact structure, convenient installation,large oil flow capacity,small pressure loss,and convenient replacement of filter elements.

2.Performance and characteristics

1).Easy to install and connect,simplify the system pipeline:

RFA-400×10L-Y/C is directly installed on the fuel tank cover,the filter head is exposed outside the fuel tank,the oil return cylinder is immersed in the fuel tank, and the oil inlet is connected with a pipe and a flange,which simplifies the system pipeline and makes the system.The layout is relatively compact,and the installation and connection are more convenient.

2).Set the filter element pollution transmitter and oil bypass valve to improve the reliability of the hydraulic system:

When the filter element FAX400X10 is blocked by pollutants or the system liquid temperature is too low,flow pulsation and other factors cause the oil inlet pressure to be 0.35MPa,the signaling device will send out a signal indication.The filter element should be replaced in time or the oil temperature should be increased.If it is impossible to stop immediately to deal with these failures,the bypass valve located at the lower part of the filter element will automatically open (the opening pressure of the bypass valve is 0.4MPa) to protect the normal operation of the filter and hydraulic system.

3).The design adopts direct return oil filter,which makes it very convenient to replace the filter element or refuel the oil tank:

Just unscrew the filter cover (cleaning cover) to replace the filter element or refuel the oil tank,and there are 2 MI8×1.5 oil ports on the filter head,which can be installed on any side or a small amount of oil in the system can be returned For fuel tank filtration.

4).With liquid diffuser:

The diffuser is set at the bottom of the oil return cylinder,which can make the oil return medium flow into the oil tank smoothly,and it is not easy to generate air bubbles, thereby reducing the re-entry of air and weakening the turmoil of deposited pollutants.

5).The filter element is made of glass fiber filter material:

It has the advantages of high filtration precision,large oil passage capacity,small original pressure loss,and large dirt holding capacity.The filtration accuracy is calibrated by absolute filtration accuracy,the filtration ratio β3, 5, 10, 20≥200, and the filtration efficiency n≥99.5%, meeting the ISO standard.

RFA-400×10L-Y/C Leemin Tank mounted min-type Return Oil Filter

RFA-400×10L-Y/C Leemin Tank mounted min-type Return Oil Filter

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)