Description:

Our manufactured 311365/01.NL63.10VG.30.E.P. hydraulic oil filter elements are designed to meet or exceed the quality and performance of original Internormen filters,ensuring superior filtration performance and long-lasting durability. 311365/01.NL63.10VG.30.E.P. oil filter uses our fiberglass media and durable design to provide reliable and consistent performance throughout its service life,even in harsh operating environments.With DKFILTER,you can be confident that you are getting a reliable and high-quality replacement filter that will keep your system running smoothly.

Performance Parameters:

| Item | Value |

|---|

| Length | 6.3 inches |

| Outside Diameter | 1.75 inches |

| Filtration accuracy | 10 μm |

| By-pass.... | No |

| Filter Material | Fiberglass、Wire Mesh |

| Seal | Viton (Fluorocarbon) |

| End Cap | Corrosion Resistant Steel..... |

| Center Tube | Corrosion Resistant Steel |

Filter Material:

This 311365/01.NL63.10VG.30.E.P. oil filter is a high pressure filter element,the end caps and center tube are used corrosion resistant steel and all the filter can bear 3000 psid pressure with high performance,increasing efficiency,keeping fluids clean,and ensures smoother operation. 311365/01.NL63.10VG.30.E.P. oil filter is engineered to ensure your hydraulic system operates smoothly,offering a versatile solution for various applications.

• All glassfiber media aggregator combines deep particle filtration with deep coalescence structure.

• The all-glass fiber design has a continuous thinner dielectric layer to achieve deep filtration of particles.

• The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores.

Filter Features:

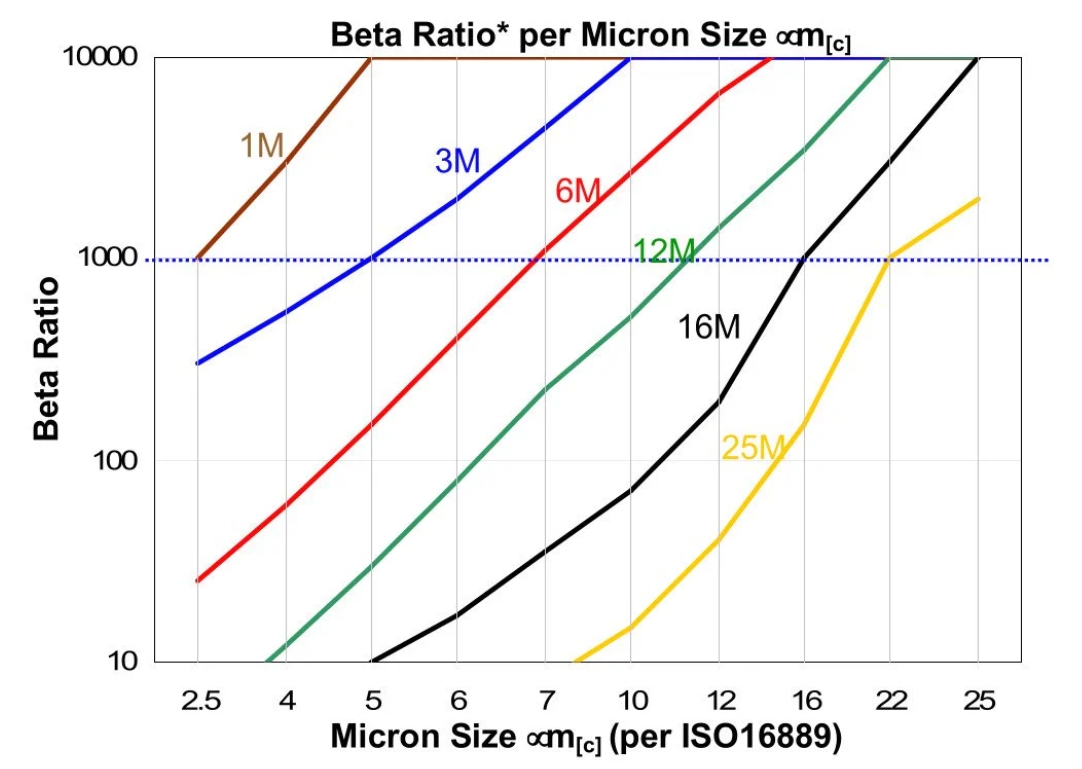

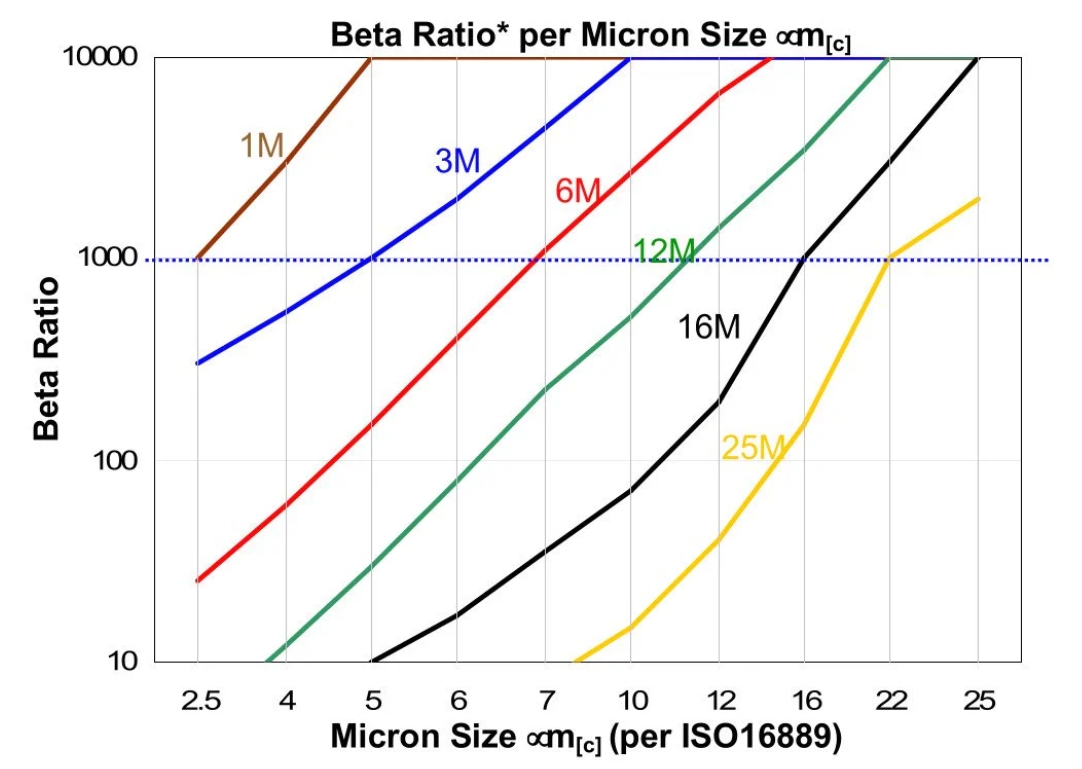

We make 311365/01.NL63.10VG.30.E.P. oil hydraulic filter is Beta grade. Excellent filtration performance. The Beta X = 1000 number means that for every 1000 particles of size x in the fluid, on average only one particle will pass through the filter.

Filter Wash:

The 311365/01.NL63.10VG.30.E.P. hydraulic oil filter is stainless steel mesh element can be cleaned again after use,it can save you much cost.However,only a certain cleaning level (percentage) can be achieved.For best results,components should be cleaned using professional equipment.But cleaning results are unpredictable.It depends a lot on various conditions.

(1) Dip the filter element in light oil and rotate thoroughly.

(2) Clean off dirt by scrubbing the element with a brush parallel to the pleats.

(3) Clean off dirt with an air spray gun.

(4) Rinse well.

(5) Dry using an air spray gun.

Notes:

It must be noted that during each cleaning process,approx. 80-90% of the initial filter area can be recovered each time,that is,after 4-5 cleaning cycles,the result (cleaning cost and service life) may not be economical.We will be happy to send you the operating manual with further information on cleaning.

Application:

311365/01.NL63.10VG.30.E.P. oil filtration element can be used for many types of industrial fluids:

filtering hydraulic fluid

diesel

machining fluids

lubricating oil

coolants

gasoline

process fluids

turbine and compressor lube oils

synthetic lubricants etc.

Test Standards:

Before delivery, Our manufactured 311365/01.NL63.10VG.30.E.P. hydraulic oil filter will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

311365/01.NL63.10VG.30.E.P.INTERNORMEN hydraulic oil filter

311365/01.NL63.10VG.30.E.P.INTERNORMEN hydraulic oil filter

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)