Introduction:

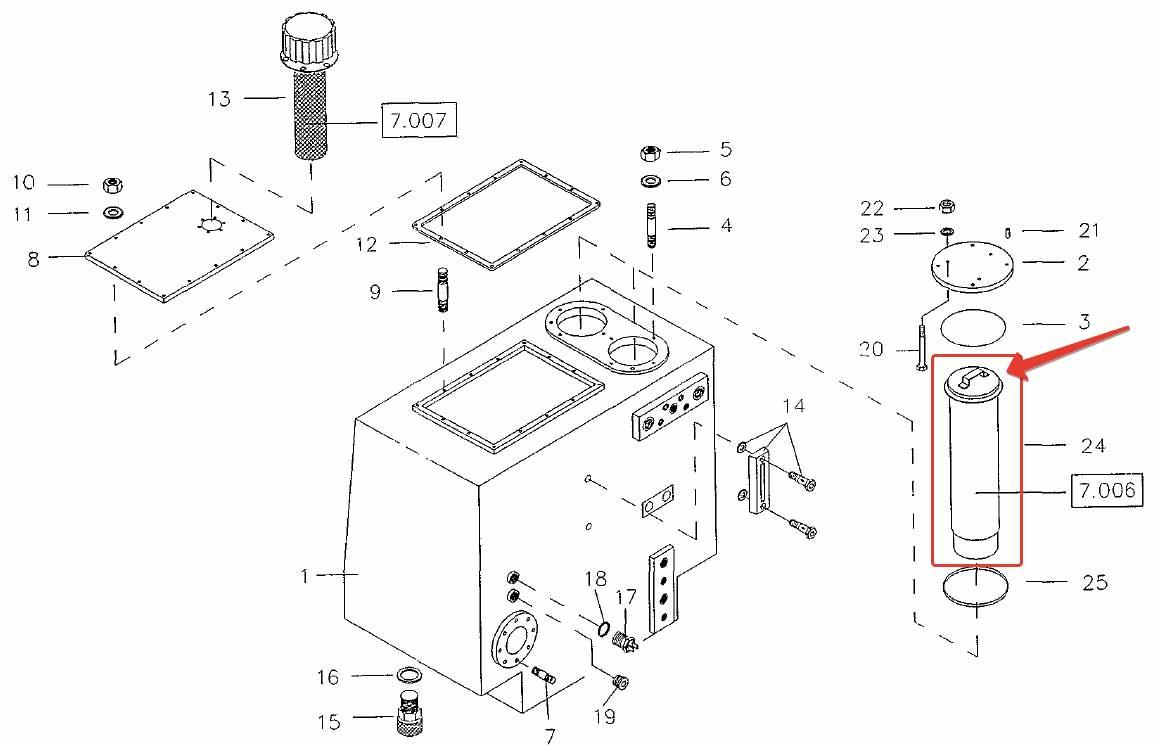

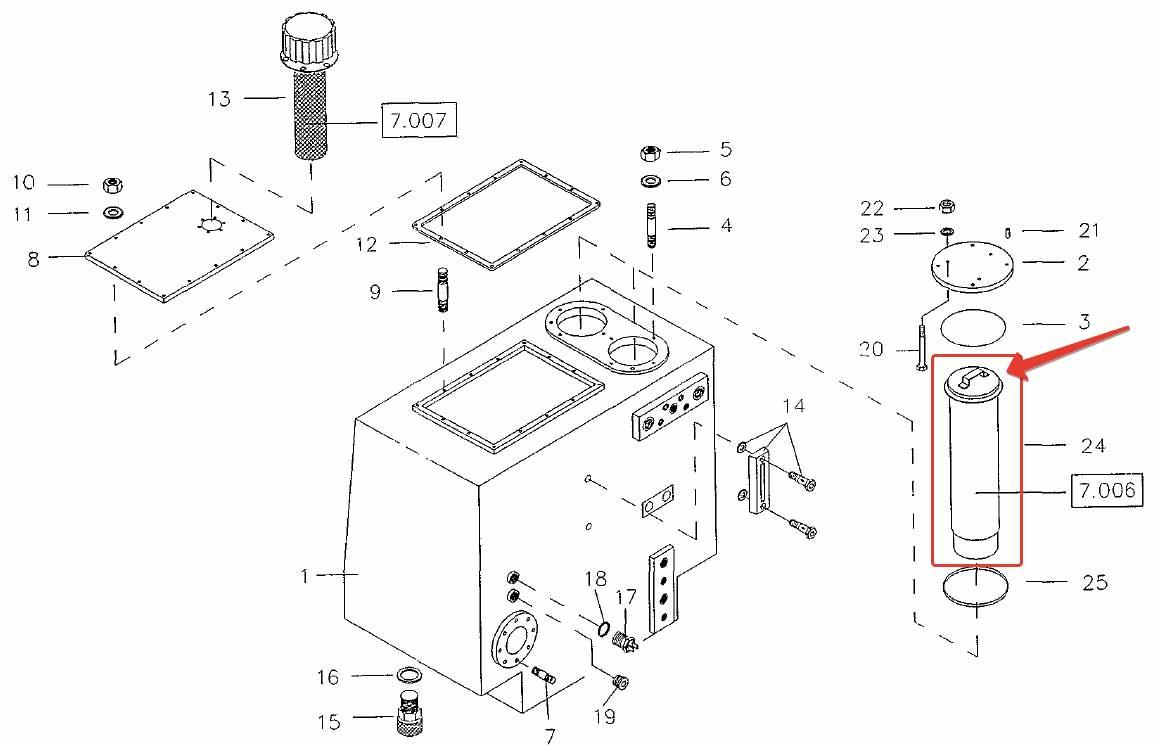

K3.1370-76/5003660426 hydraulic oil filter element is an indispensable part of the pipeline series for conveying media.It is usually installed at the inlet end of the hydraulic system to filter out metal particles and polluting impurities in the fluid medium to protect the normal operation of machinery and equipment.

The application range of K3.1370-76/5003660426 hydraulic oil filter is very wide,covering almost all walks of life:steel,electric power, metallurgy,shipbuilding,aviation,papermaking,chemical industry,machine tools and engineering machinery,construction machinery and other fields.

Application:

ATLAS 350MH

ATLAS 352M

DEMAG H65

DEMAG H95

FUCHS 320MHL

FUCHS 331MHL

FUCHS 331MHL

FUCHS 331MHL

FUCHS 331MHL

FUCHS 335MHL

FUCHS 340FMHL

FUCHS 340MHL

FUCHS 340MHL

FUCHS 350D

FUCHS 350MHL

FUCHS 350MHL

FUCHS 350MHLSERIEA

FUCHS 360MHL

FUCHS 464MHL

FUCHS MHL350E

FUCHS MHL360E

Filter Feature:

We make K3.1370-76/5003660426 hydraulic oil filter is Beta grade. Excellent filtration performance. The Beta X = 1000 number means that for every 1000 particles of size x in the fluid, on average only one particle will pass through the filter.

Maintenance methods:

1. Drain the original hydraulic oil before replacement,check the oil return filter element,oil suction filter element,and pilot filter element to see if there are iron filings,copper filings or other impurities attached.If so,there may be a hydraulic component failure.After inspection and elimination, clean the system.

2. When changing the hydraulic oil,all hydraulic oil filters (return filter,oil suction filter,pilot filter) must be replaced at the same time,otherwise it is equivalent to not changing at all.

3. Identify the grade of the hydraulic oil.If hydraulic oils of different grades and brands are not mixed, they may react and deteriorate to produce floc.It is recommended to use the oil specified for the excavator.

4. The oil suction filter element must be installed before refueling.The nozzle covered by the oil suction filter element directly leads to the main pump.If impurities enter,it will accelerate the wear of the main pump,or it will cause the pump to pump.

5. Add oil to the standard position.There is usually an oil level gauge on the hydraulic tank. Check the fluid level gauge.Pay attention to the parking method.Generally,all cylinders are retracted,that is,the forearm and bucket are fully extended and landed on the ground.

6. After refueling,be sure to bleed air from the main pump.Otherwise,the entire vehicle may be temporarily inactive,the main pump may make abnormal noise (air sonic boom), or air pockets may damage the main pump.The way to exhaust air is to loosen the pipe joint directly on the top of the main pump and fill it up directly.

Test standards:

Before delivery, Our manufactured K3.1370-76/5003660426 hydraulic oil filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

5003660426/K3.1370-76 Argo Machinery Oil Filter Element

5003660426/K3.1370-76 Argo Machinery Oil Filter Element

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)