Introduction:

JPM2609-10-W jonell separator filter is a precision filter element designed for natural gas, liquefied gas, and industrial gas systems. JPM2609-10-W oil fuel filter is also suitable for efficient filtration of hydraulic oil, lubricating oil and other fluids to extend the normal service life of mechanical equipment.

Performance Parameters:

| Parameter | Value |

|---|

| Length | 9.75 inches |

| Outside Diameter..... | 2.63 inches |

| Inside Diameter | 1.06 inches |

| Change-out pressure | 25 psid |

| Max. Operating Collapse | 75 psid |

| Max. Temp | -30℃ ~ 80℃ |

| Filtration Accuracy | 3μm 5μm 10μm |

| Flow Rate | 20L/min ~ 100L/min |

| Filter Material | Teflon, Glassfiber |

| Seal | Buna-N |

| End Caps | Corrosion Resistant Steel |

| Center Tube | Corrosion Resistant Steel |

Materials Structural Advantages:

• Multi-layer composite material:

• • Outer layer: stainless steel woven mesh (impact-resistant, anti-structural deformation).

• • Support layer: 304 stainless steel skeleton (corrosion-resistant, strong pressure bearing).

• • Filter layer: glass fiber + polyester fiber (gradient density design, taking into account both dirt holding capacity and accuracy).

• Coalescence separation technology:

• • Using oleophilic and hydrophobic materials to achieve oil droplet aggregation and rapid sedimentation of water phase, separation efficiency>99.9%.

Filter Material:

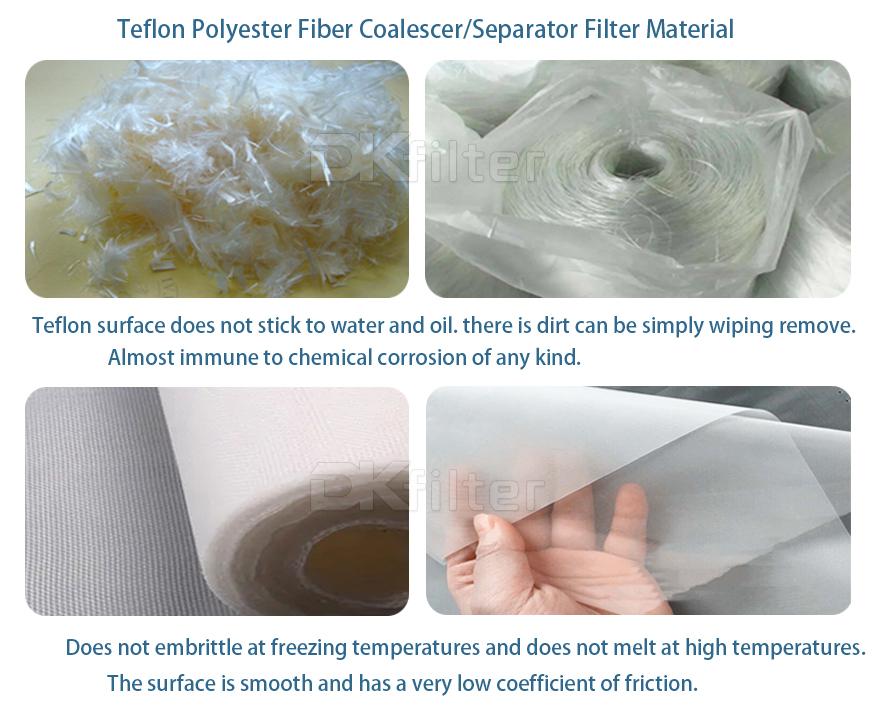

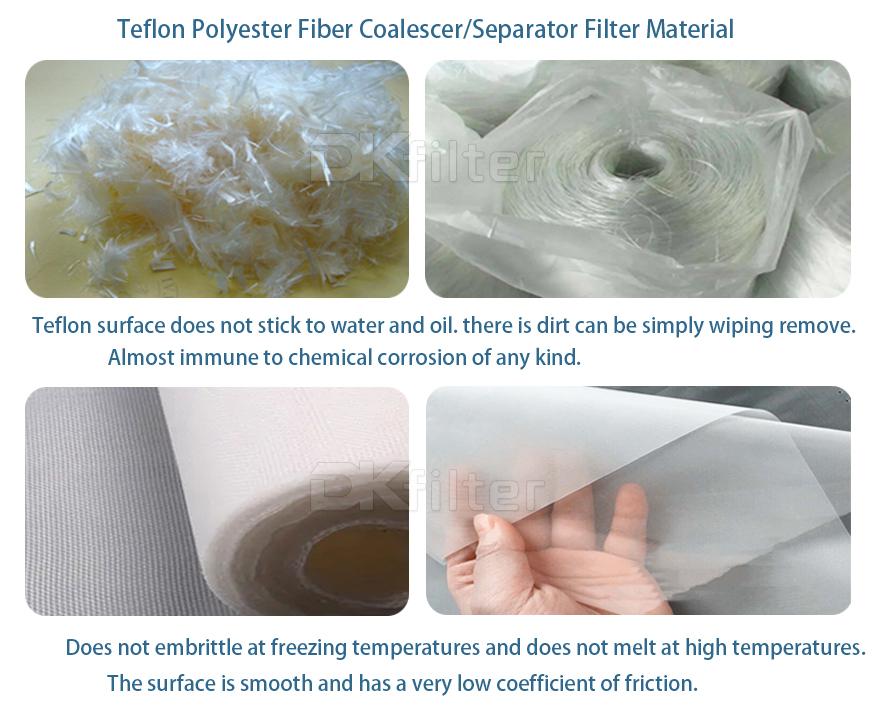

Our Manufactured JPM2609-10-W jonell fuel separator cartridge replacement uses high-performance Teflon filter material. Moisture resistance: the surface of Teflon does not stick to water and oil. If there is dirt, can be removed by simply wiping it. Temperature resistance: does not become brittle at freezing temperatures and does not melt at high temperatures. Wear resistance: smooth surface has a very low coefficient of friction. Corrosion resistance: almost immune to any kind of chemical corrosion.

Test Standards:

Before delivery, Our JPM2609-10-W jonell oil liquid separator filter will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

JPM2609-10-W JONELL Natural Gas Fuel Coalescer Separator Filter Replacement

JPM2609-10-W JONELL Natural Gas Fuel Coalescer Separator Filter Replacement

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)