Introduction:

CAA56-5SB facet coalescer cartridge is used to remove particulate contaminants from hydrocarbon fuels and condense highly dispersed emulsified water particles to purify fuel oil. The CAA56-5SB uses a single unit structure to reduce the number of gaskets and improve overall reliability. The all-glass fiber design has a continuous thinner dielectric layer to achieve deep filtration of particles.

Performance Parameters:

| Item | Value |

|---|

| Length | 57.0 inches |

| Inside Diameter | 3.5 inches |

| Outside Diameter | 6.0 inches |

| Filtration accuracy | 99.9% |

| Maximum Pressure Differential.... | 75 psi, 5.2 bar |

| Maximum Operating Temperature..... | 66-71°C, 150-160°F..... |

| Changeout Pressure Differential..... | 15 psi, 1 bar |

| Filter Material | Fiberglass |

| Seal | Buna-N |

| End Caps | Injection moldedglass-filled nylon |

| End Caps Configuration..... | Threaded Base..... |

More CAA Series

CAA11-5, CAA22-5

CAA33-5, CAA43-5

CAA56-5, CAA56-5SB

CAA14-5, CAA22-5SB

CAA33-5SB, CAA43-5SB

CAA14-5SB, CAA28-5

CAA38-5, CAA38-5SB

CAA16-5SB CAA28-5SB

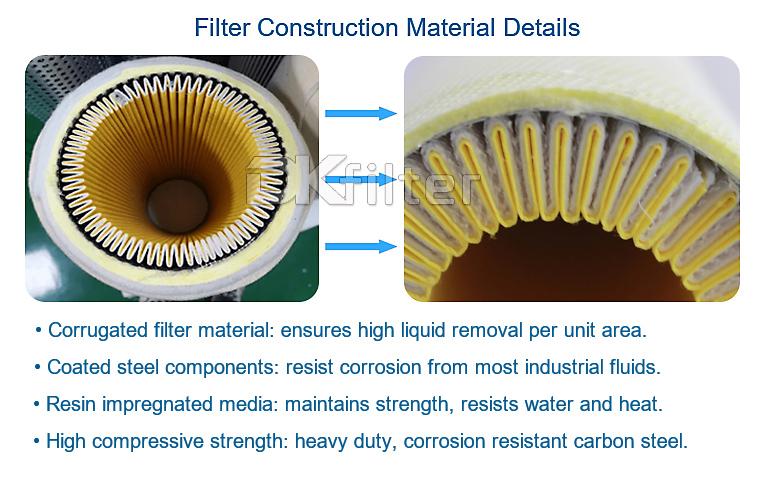

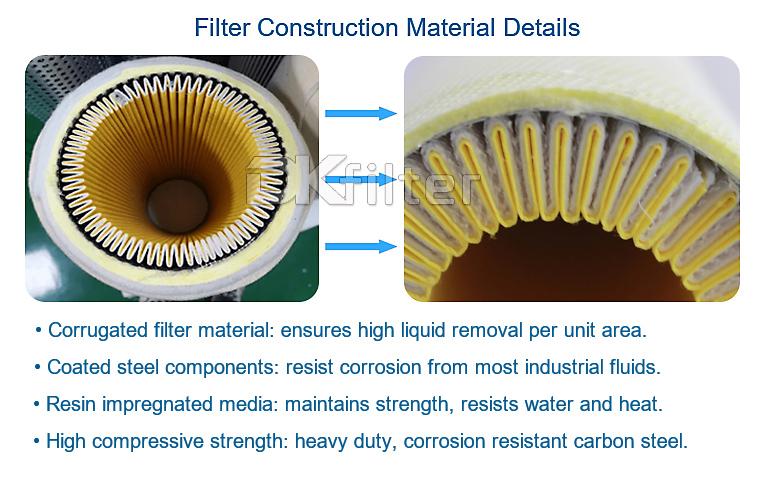

Structure Materials:

• Stainless steel metal support

• Polymeric outer drainage layer to prevent liquid reentrainment

• Resin bonded glass fiber coalescer media designed in a pack to handle large quantities of liquid

• Oleophobic/hydrophobic treatment to improve liquid drainage,protect from liquid slugs and minimize saturated pressure drop

Filter Material:

We make CAA56-5SB aviation fuel coalescer filter cartridge use all glassfiber media aggregator combines deep particle filtration with deep coalescence structure.

• Use pleated ripples and separate materials to keep the pleats open for full use.

• The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores.

• Have one or more layers of pleated media inside molded fiberglass laminated cylinders to provide a larger particle filtration surface area.

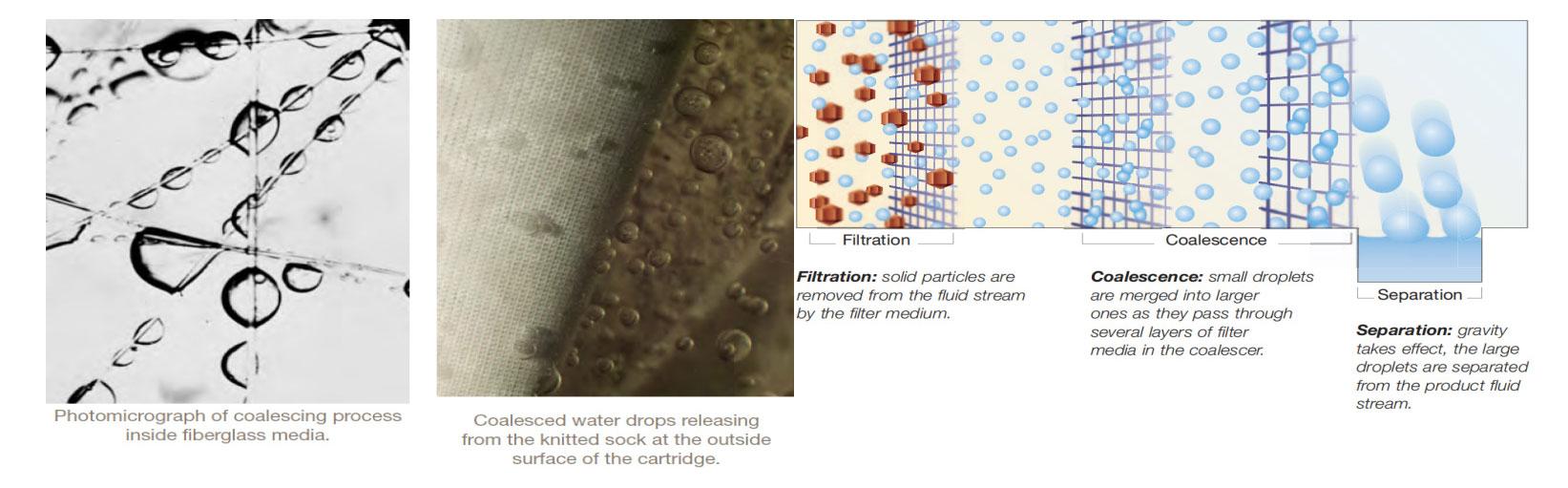

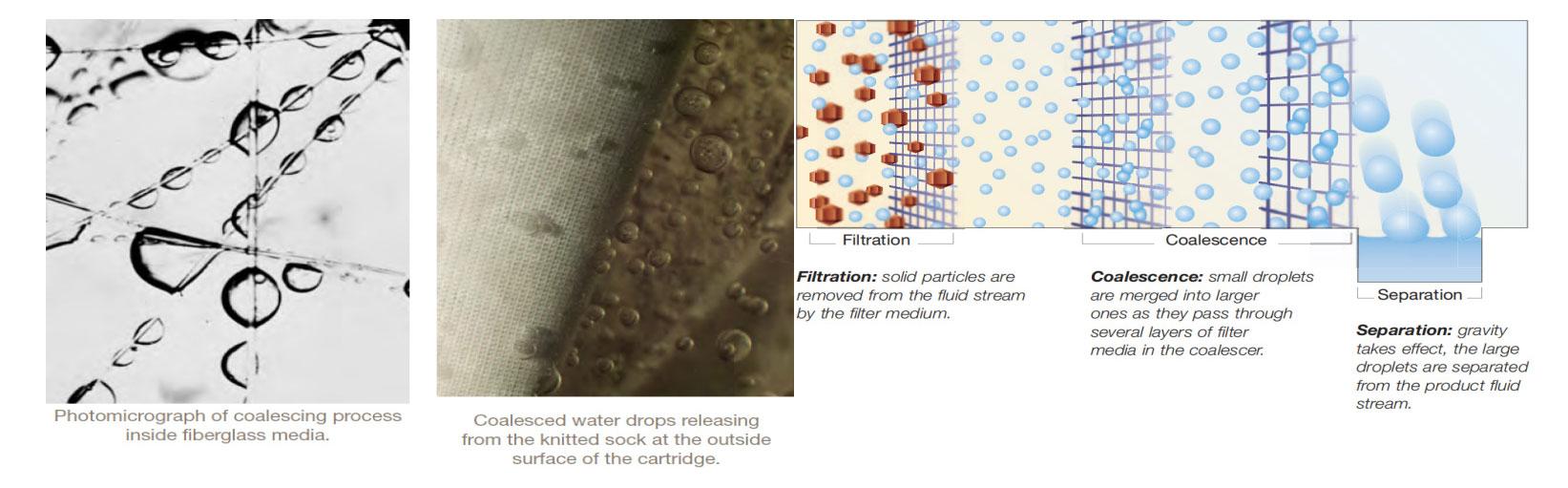

Work principle:

CAA56-5SB high-efficiency coalescers merge small droplets of liquid into larger ones as the fluid stream passes through several layers of filter media,each with progressively larger pores.

As droplets compete for the open pores,they coalesce forming larger droplets.These larger droplets are easier to separate from the continuous phase fluid.

The CAA56-5SB coalescer size and type are determined by numerous factors:physical properties of the fluid,flow rate,process conditions and chemical compatibility with process fluids and additives.

Test Standards:

Before delivery, Our manufactured CAA56-5SB coalescer filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent coalescers cartridge filter manufacturer

Parker & Velcon

PECO & Facet

Faudi

Pall

Other types are available on request

CAA56-5SB Facet CAA Series Aviation Approved Monitor Coalescer Filter Element

CAA56-5SB Facet CAA Series Aviation Approved Monitor Coalescer Filter Element

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)