Introduction:

The FO-644PLF5 pleated coalescer filter is used to remove solid particulate contaminants and water from aviation jet fuel, diesel, industrial fluids, and insulating oils used in power utilities. The FO-644PLF5 coalescing filter outer media layer filters out silt, rust, and other particulate contaminants. The inner layer absorbs water and chemicals. This improves the cleanliness of the fuel oil fluid and protects the long-term, efficient, and safe operation of industrial equipment.

Performance Parameters:

• Collapse: 75 psi

• Operating pH range: 5 - 9

• Micron ratings: 0.25 - 75

• Nominal filtration efficiency: 98%+

• Changeout differential pressure: 25 psid

• Maximum operating temperature: 250°F (121.1°C)

Material Properties:

Our manufactured FO-644PLF5 pleated coalescer filter cartridge media is made from high quality hydrophobic pleated cellulose material. The outer media layer filters out silt, rust and other particulate contaminants, while the inner layer absorbs water and chemicals. FO-644PLF5 fuel coalescer filter element is widely used in various industrial industries such as power generation, oil and gas, petrochemicals, aerospace, etc.

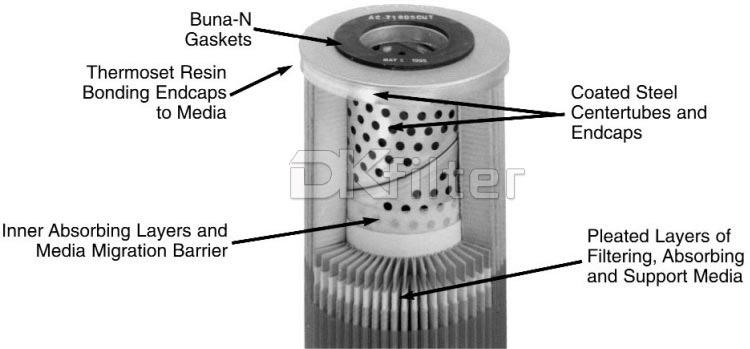

• All metal parts are treated for corrosion protection

• Composite fiber and pleated paper media high surface area pleated core.

• Buna-N gaskets - other materials available upon request

Performance Features:

• Coated steel parts: Resistant to corrosion by most industrial fluids.

• Resin impregnating medium:Maintains strength,resists the effects of water and heat.

• Buna-N Gaskets: The best universal gasket material to ensure reliable sealing in most fluids.

• Large surface area: Allows high flow rates,low initial pressure drop,maximum contaminant capacity.

• Thermosetting adhesive material: Durable end caps and media bonding can prevent internal bypass.

Filter Feature:

We make FO-644PLF5 oil filter is Beta grade. Excellent filtration performance. The Beta X = 1000 number means that for every 1000 particles of size x in the fluid, on average only one particle will pass through the filter.

Notes:

When the FO-644PLF5 coalescing filter element reaches its water storage limit, the media expands closed and the pressure differential increases rapidly. This signals the operator that the filter element must be replaced.

Test Standards:

Before delivery, Our manufactured FO-644PLF5 oil filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent coalescer cartridge filter manufacturer

Parker & Velcon

PECO & Facet

Faudi

Pall

Other types are available on request.

FO-644PLF5 VELCON Pleated Coalescer Filter Cartridge Replaces

FO-644PLF5 VELCON Pleated Coalescer Filter Cartridge Replaces

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)