Introduction:

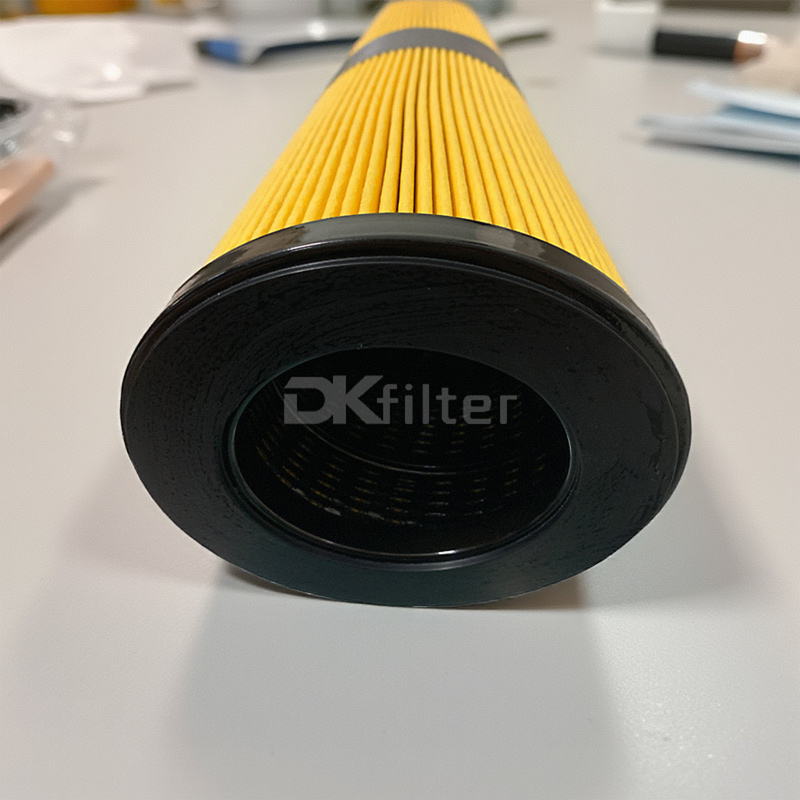

SO-633PLBZ oil liquid separator filter cartridge is used to remove particulate contaminants and free water from oil, fuel or other fluids. SO-633PLBZ separator filter element is used as the second stage in the filter separator container to ensure the required cleanliness standards of the fluid. We make SO-633PLBZ oil separator use high-quality Teflon, it is a cleanable, reusable, and highest quality separation filter element available in a variety of size configurations. The coated filter is wrapped in a treated perforated metal shell that is stitched folded and secured with metal clips. The screen is coated with Teflon for more effective water resistance, ensuring long-term trouble-free use.

Performance Parameters:

| Item | Value |

|---|

| Length | 33.0 inches |

| Outside Diameter | 6.0 inches |

| Inside Diameter | 3.5 inches |

| Filtration accuracy...... | 99.9% |

| pH range | 4 - 9 |

| Max Temperature | 200°F |

| Filter Material | Micro Fiberglass and Cellulose, Pleated Paper |

| Seal | Buna-N |

| Removal Effciency | Effuent solids <0.15 mg/liter |

| Center Tube | Corrosion Resistant Steel |

SO Series Structural Diagram:

SO-633PLBZ fuel oil filter cartridge function is to improve the cleanliness of oil products, ensure the quality requirements of oil products, and ensure the long-term, efficient and safe operation of industrial equipment.

....

Performance Features:

Our manufactured SO-633PLBZ separator filter cartridges are guaranteed to meet or exceed OEM filter requirements.

• Standard EI 1581 applies.

• Applications: Aviation, Industrial.

• All metal parts are anti-corrosion treated.

• Filtration levels are available in 1, 2, 3 and 5 micron.

• Spiral wound cores reduce weight and reduce shipping costs.

• The design adopts an integrated structure for easy installation and replacement.

Filter Material:

We make SO-633PLBZ separator filter uses a single unit structure to reduce the number of gaskets and improve overall reliability. SO-633PLBZ separator oil cartridge filter have one or more layers of pleated media inside molded fiberglass laminated cylinders to provide a larger particle filtration surface area. Use pleated ripples and separate materials to keep the pleats open for full use.

• All metal parts are treated for corrosion protection.

• Composite fiber and pleated paper media high surface area pleated core.

• Buna-N gaskets - other materials available upon request.

Material performance curve:

SO-633PLBZ hydraulic separator oil filter cartridge filter media is made from high quality hydrophobic pleated cellulose material. The outer media layer filters out silt, rust and other particulate contaminants, while the inner layer absorbs water and chemicals.In the oil, gas and water filtration equipment system, coalescing pleated filters belong to the category of coalescers and separators. SO-633PLBZ fuel gas filter element is widely used in various industrial industries such as power generation, oil and gas, petrochemicals, aerospace, etc.

....

Test Standards:

Before delivery, Our manufactured SO-633PLBZ oil filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent separator cartridge filter manufacturer

Parker & Velcon

PECO & Facet

Faudi

Pall

Other types are available on request.

SO-633PLBZ Parker Velcon Oil Separator Filter Replacement

SO-633PLBZ Parker Velcon Oil Separator Filter Replacement

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)