Introduction:

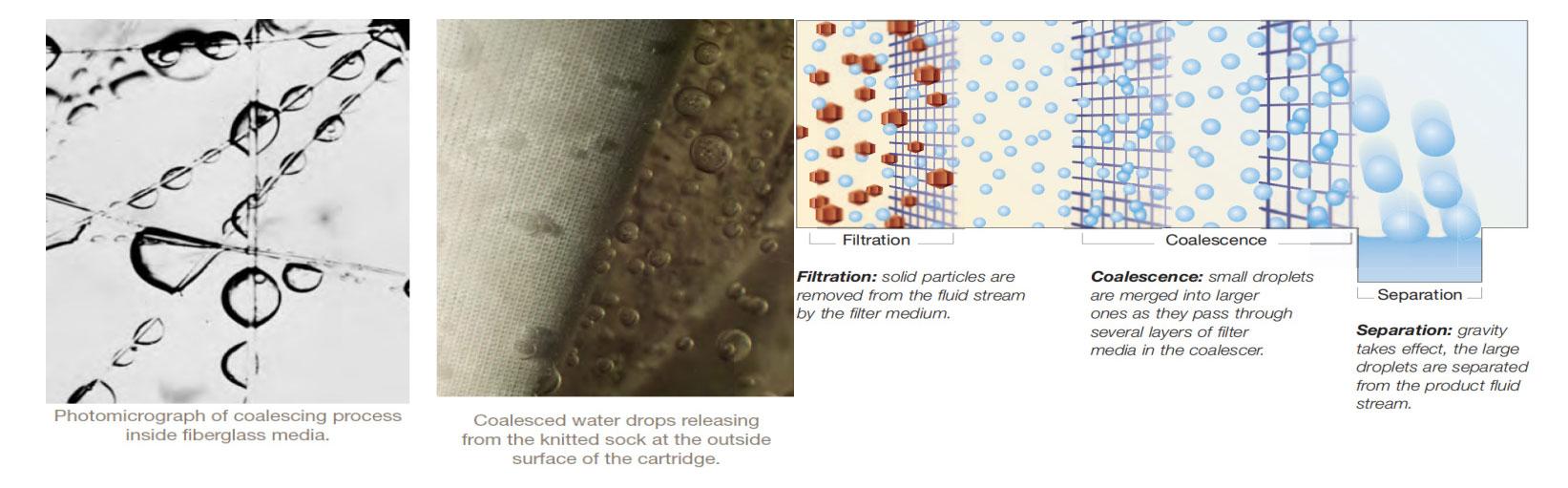

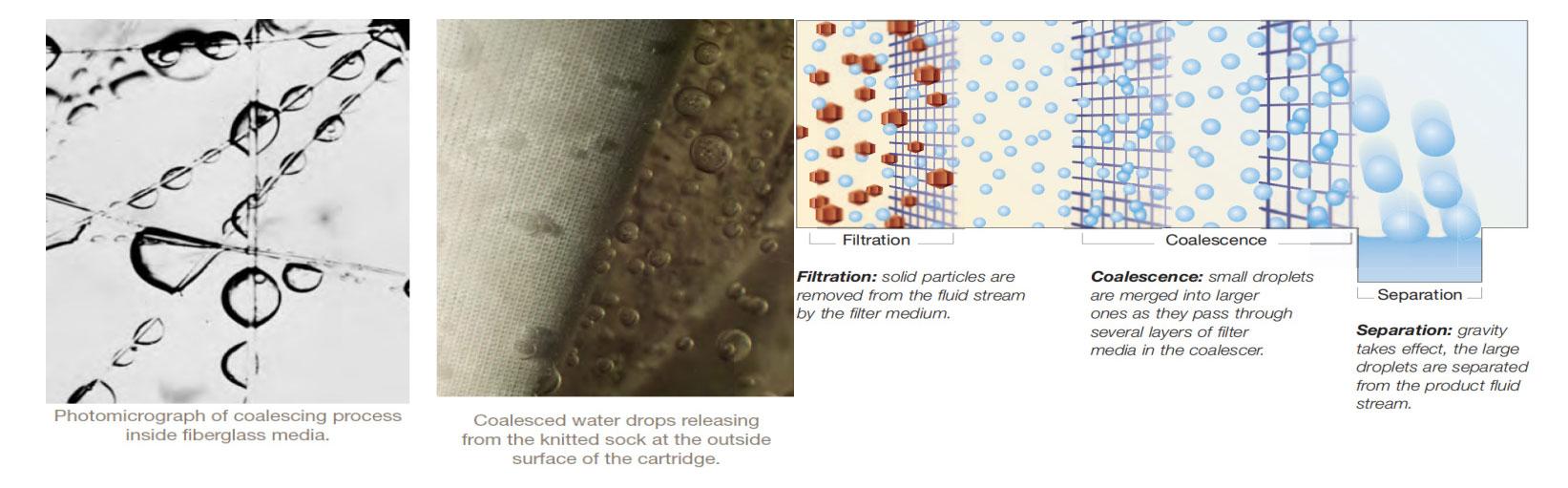

CC-63385 Parker velcon coalescer filter is used to remove particulate contaminants from hydrocarbon fuels and concentrate highly dispersed emulsified water particles to purify the fuel. The CC-63385 coalescing filter element mainly uses surface-treated glass fiber or polyester fiber as the coalescing medium.

The structure of the CC-63385 coalescer cartridge filter material is specially designed so that the filter medium has good coalescing performance. Coalescing filters are used in oil and gas coalescing purification and filtration equipment systems. The filter media uses high-quality hydrophobic deep glass fiber coalescing media.

Performance parameters:

| Item | Value |

|---|

| Length | 34.0 inches |

| Inside Diameter | 3.25 inches |

| Outside Diameter | 6.0 inches |

| Filtration accuracy | 99.9% |

| Seal | Buna-N |

| Filter Material | Glass fiber filter paper |

| Center Tube.... | Corrosion Resistant Steel |

| End caps | Injection moldedglass-filled nylon |

| Working Medium | Hydraulic oil、Fuel gas etc |

Structure Materials:

• Stainless steel metal support

• Polymeric outer drainage layer to prevent liquid reentrainment

• Resin bonded glass fiber coalescer media designed in a pack to handle large quantities of liquid

• Oleophobic/hydrophobic treatment to improve liquid drainage,protect from liquid slugs and minimize saturated pressure drop

Performance Parameters:

• Nitrile rubber gasket.

• Aluminum center tube.

• The pH range is 4 to 9.

• High density fiberglass medium.

• Maximum differential pressure rating75 psi.

• The maximum working temperature is between 70°C and 80°C.

Structrue Materials:

We make CC-63385 aviation fuel coalescer filter cartridge screw base ends are injection molded,glass-filled nylon.This screw base material offers superior strength and ease of maintenance—uniform threads,no shrinkage,no galling and no gasket to recover. A permanently affixed Buna-N gasket seals against the V-type knife edge mounting adaptor to provide a positive seal.It will not separate from the cartridge during installation or change out.

• All metal components are treated against corrosion

• Screw base ends are injection molded, glass-filled nylon with locked-in gaskets

• Buna-N gaskets—other materials are available on request

CC-63385 coalescence filter characteristics:

CC-63385 Parker velcon screw base end coalescer adopts a single unit structure to ensure oil flow. The CC-63385 coalescer filter has multi-layer pleated media to provide a larger particle filtration surface area. Droplets of oil, water and other liquids are captured by the ultra-fine fibers inside the coalescer to achieve a greater degree of clean filtration.

Our manufactured CC-63385 Parker velcon coalescing filter assemblies are guaranteed to meet or exceed OEM filter requirements.

Test Standards:

Before delivery, Our manufactured CC-63385 coalescer element will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent coalescers cartridge filter manufacturer

Parker & Velcon

PECO Facet

Faudi

Pall

Other types are available on request

CC-63385 Velcon Coalescer Filter Cartridge Replacement

CC-63385 Velcon Coalescer Filter Cartridge Replacement

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)