Introduction:

JFG-336 jonell gas fuel coalescing filter is used in oil and gas coalescing purification and filtration equipment systems to remove water and dirt from oil, gas and other gases, and clean oil and gas categories such as liquefied gas, diesel, industrial liquids and insulating oil of electric power facilities. JFG-336 jonell coalescer filter cartridge can improve the cleanliness of oil products, ensure the quality requirements of oil and gas products, and ensure the long-term, efficient and safe operation of industrial equipment.

Performance Parameters:

| Item | Value |

|---|

| Length | 36.0 inches |

| Inside Diameter | 3.15 inches |

| Outside Diameter | 4.5 inches |

| Filtration accuracy | 0.1 µm |

| Filter Material | Multilayer fiberglass |

| Seal | Buna-N |

More Filter Model:

JMG-24-R

JMG-36-R-K

JPMG-30226

JPMG-36346C-V

JPMG-36349-V

JFG-336-10-MA 304

Structure Materials:

• Stainless steel metal support

• Polymeric outer drainage layer to prevent liquid reentrainment

• Resin bonded glass fiber coalescer media designed in a pack to handle large quantities of liquid

• Oleophobic/hydrophobic treatment to improve liquid drainage,protect from liquid slugs and minimize saturated pressure drop

Performance Features:

• High oil flow.

• Low flow resistance.

• Heavy duty construction.

• Good moisture resistance.

• Easy to install and replace.

• High dust holding capacity.

• Good temperature resistance.

• Ideal for synthetic or conventional oil purification.

• Economical, practical, durable and long service life.

Filter Material:

We make JFG-336 jonell gas fuel coalescer filter replacement overall construction consists of an expanded carbon steel core, which ensures the coalescer filter element is structurally tough, retaining its shape and uniform pressure differential under pressure. JFG-336 oil coalescer filter outer layer surrounds a pleated element of fiberglass of varying density that acts as the coalescing portion of the filter, and the outer layer drains coalesced liquid. JFG-336 coalescing filter cartridge use all glassfiber media aggregator combines deep particle filtration with deep coalescence structure.

• Use pleated ripples and separate materials to keep the pleats open for full use.

• The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores.

• Have one or more layers of pleated media inside molded fiberglass laminated cylinders to provide a larger particle filtration surface area.

Filtering Mechanism:

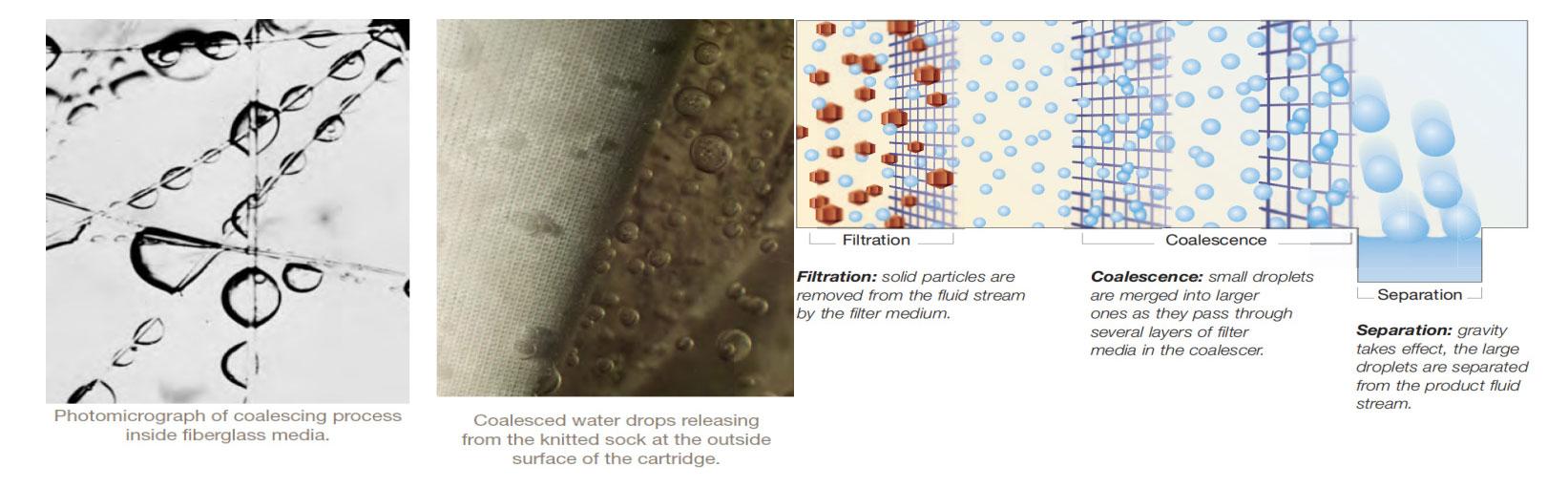

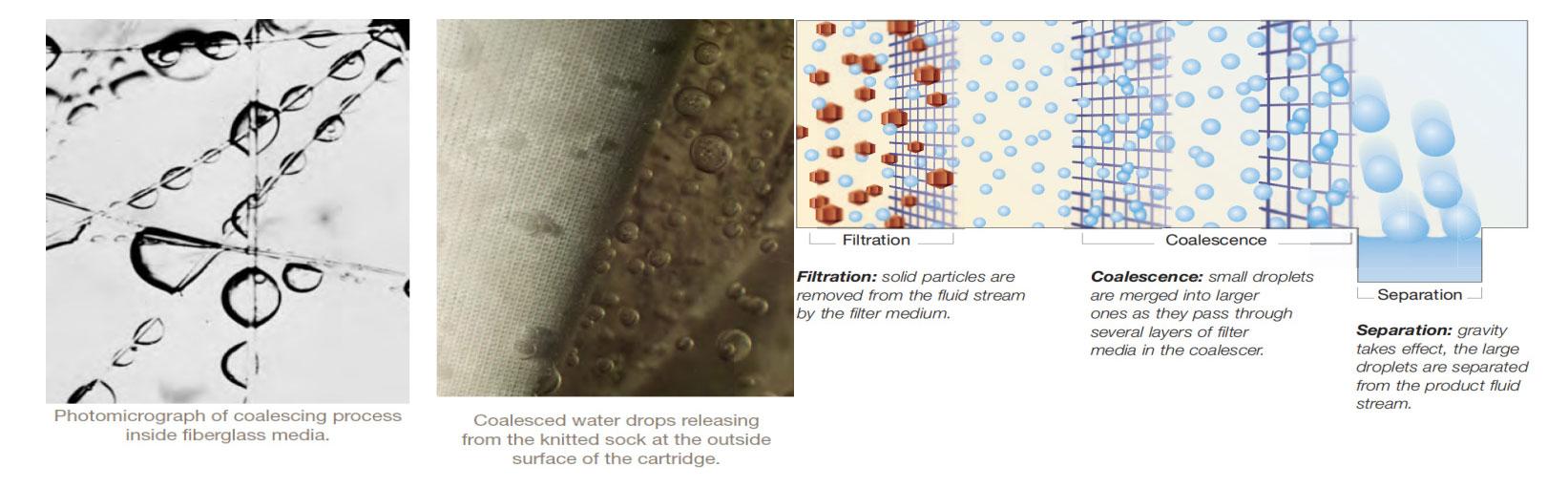

JFG-336 jonell coalescing filter element mainly uses surface-treated glass fiber or polyester fiber as the coalescing medium. The structure of the filter material is specially designed so that the filter medium has good coalescing properties.Belongs to coalescer filter cartridge category.

Droplets of liquids such as oil and water are captured by microfibers inside the coalescer. These micron-sized fibers form tortuous airflow channels, forcing solid particles and liquid mist droplets to undergo three processes: inertial collision, diffusion interception and diffusion.

Test Standards:

Before delivery, Our manufactured JFG-336 fuel coalescer filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Applictions:

JFG-336 coalescing filter elements are widely used in various industrial industries

power generation

oil and gas filer

petrochemicals

aerospace etc.

JFG-336 jonell Gas Fuel Coalescing Filter Purifier Element

JFG-336 jonell Gas Fuel Coalescing Filter Purifier Element

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)