Introduction:

AD-21025 Parker Velcon coalescing pleated filter is used in oil and gas machinery and equipment filtration systems to remove water and dirt from oil, fuel and gas, and clean oil and gas products such as liquefied gas, diesel, industrial liquids and insulating oil of electric power facilities.

Parker Velcon AD-21025 Structure:

AD-21025 function is mainly to improve the cleanliness of oil products, ensure the quality requirements of oil products, and ensure the long-term, efficient and safe operation of industrial equipment. In the oil, gas and water filtration equipment system, coalescing pleated filters belong to the category of coalescers and separators.

.....

Technical Datas:

• Collapse:75 psi

• Operating pH range:5 - 9

• Micron ratings: from 1/4 to 75

• Nominal filtration efficiency:98%+

• Maximum operating temperature:250°F (121.1°C)

• Recommended changeout differential pressure:25 psid

Filter Material:

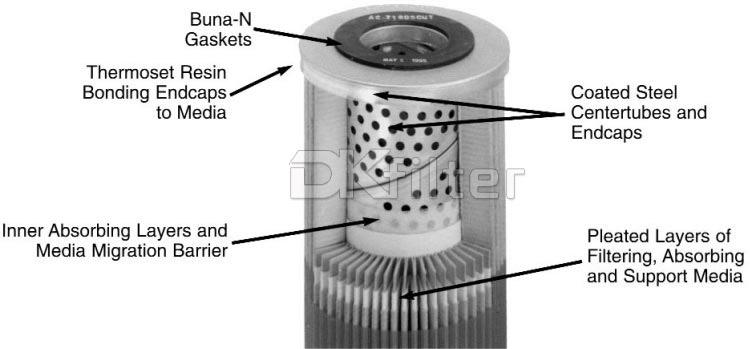

We make AD-21025 coalescing fuel oil filter uses high quality hydrophobic pleated cellulose material. The outer media layer filters out silt, rust and other particulate contaminants, while the inner layer absorbs water and chemicals. Separation filter elements are widely used in various industrial industries such as power generation, oil and gas, petrochemicals, aerospace, etc.

• All metal parts are treated for corrosion protection

• Composite fiber and pleated paper media high surface area pleated core

• Buna-N gaskets - other materials available upon request

Material Properties:

This AD-21025 oil coalescer filter cartridge media is made from high quality hydrophobic pleated cellulose material. The outer media layer filters out silt, rust and other particulate contaminants, while the inner layer absorbs water and chemicals. AD-21025 oil coalescing filter elements are widely used in various industrial industries such as power generation, oil and gas, petrochemicals, aerospace, etc.

Test Standards:

Before delivery, Our manufactured AD-21025 oil filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

AD-21025 Applications:

Gasoline

Transformer Oil

Synthetic Oil

Kerosene

Hydraulic Oil

Phosphate Ester Oil

Diesel Fuel

Turbine Lube Oil

Instrument Air

Insulating Oil

Quench Oil

Process Gases

AD-21025 Parker Velcon Seperater Coalescer Filter Cartridge

AD-21025 Parker Velcon Seperater Coalescer Filter Cartridge

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)