Introduction:

We make CS604LGH13 Pall fuel gas coalescer replacement is used to removes liquids and solids from high flow gas streams that contain high concentrations of liquids.Its media can process several times more liquid per unit area of media than conventional media and often eliminates the need for upstream bulk separation equipment. CS604LGH13 coalescing filter media is supplied in a large flow,high performance 6-inch diameter cartridge that can economically treat large gas flows in applications that require a high degree of protection from both solids and liquids.

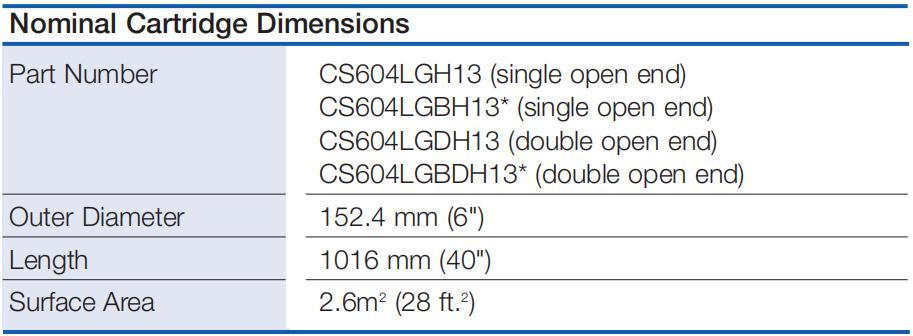

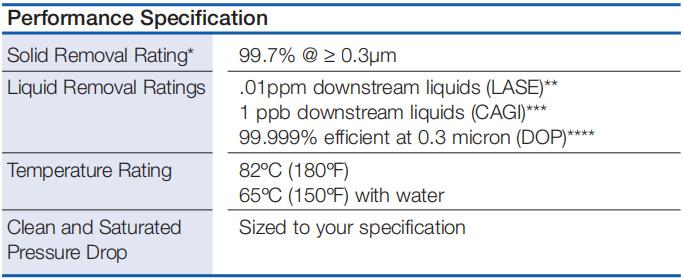

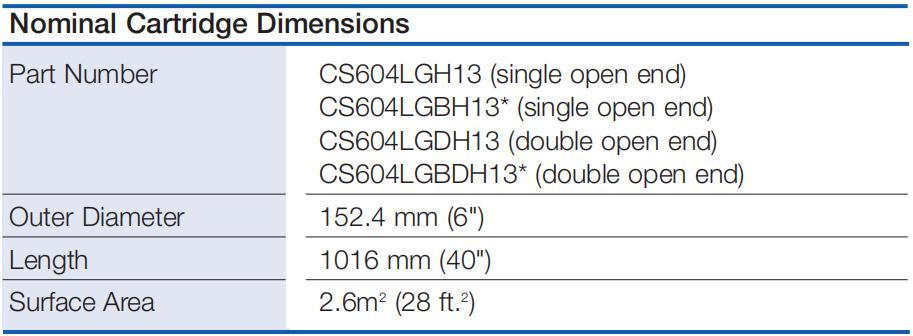

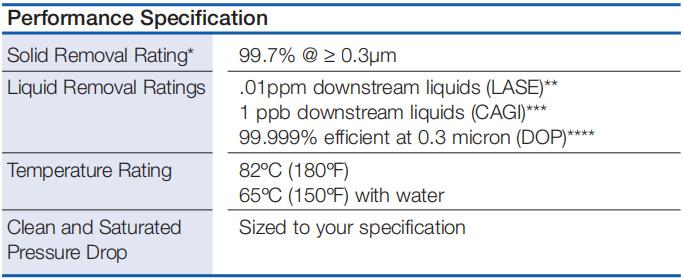

Technical Information:

• Amine compatible

• Per sodium chloride challenge test

•• Per the Pall Liquid Aerosol Separation Efficiency (LASE) Test

••• Per the modified ANSI/CAGI-400-1999 test procedure

•••• Per the Di-Octyl Phthalate (DOP) test using a monodisperse 0.3 micron aerosol

Structure Materials:

• Stainless steel metal support

• Polymeric outer drainage layer to prevent liquid re-entrainment

• Resin bonded glass fiber CS604LGH13 coalescer media designed in a pack to handle large quantities of liquid

• Oleophobic/hydrophobic treatment to improve liquid drainage,protect from liquid slugs and minimize saturated pressure drop

Filter Material:

Our Manufactured CS604LGH13 fuel gas coalescer filter cartridge screw base ends are injection molded,glass-filled nylon. With conventional media packing,the cartridge requirement may become uneconomical once the liquid concentration gets above a few hundred ppmw.The CS604LGH13 liquid gas coalescer element economically removes liquids from gas streams with high liquid loading,often eliminating the need for an upstream bulk separator.

• All metal components are treated against corrosion

• Screw base ends are injection molded, glass-filled nylon with locked-in gaskets

• Buna-N gaskets—other materials are available on request

Performance Features:

• Protecting compressors and turbines

• Protecting desiccant and catalyst beds

• Controlling injection well plugging during gas flooding

• Minimizing solution losses downstream of gas purification process units

• Cleaning dirty fuel gas to protect low Nox burners and fuel injection nozzles

• Removing lubrication oil, water,and compressor wear products from effluent gas streams

• Removing liquid aerosols from gases fed to amine sweetening and dehydration units to prevent foaming problems

Work principle:

CS604LGH13 high-efficiency coalescers merge small droplets of liquid into larger ones as the fluid stream passes through several layers of filter media,each with progressively larger pores.As droplets compete for the open pores,they coalesce forming larger droplets.These larger droplets are easier to separate from the continuous phase fluid.

The CS604LGH13 coalescer size and type are determined by numerous factors:physical properties of the fluid,flow rate,process conditions and chemical compatibility with process fluids and additives.

Test Standards:

Before delivery, Our manufactured CS604LGH13 fuel gas coalescer element will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent coalescers cartridge filter manufacturer

Parker & Velcon

PECO & Facet

Faudi

Pall

Other types are available on request

CS604LGH13 Pall SepraSol Natural Gas Coalescer Filter

CS604LGH13 Pall SepraSol Natural Gas Coalescer Filter

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)