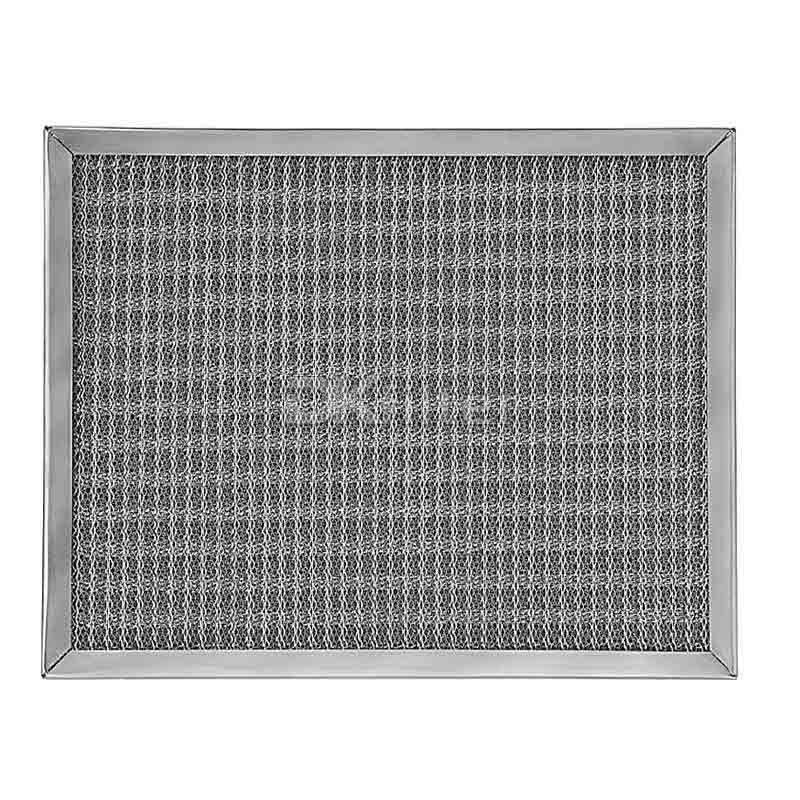

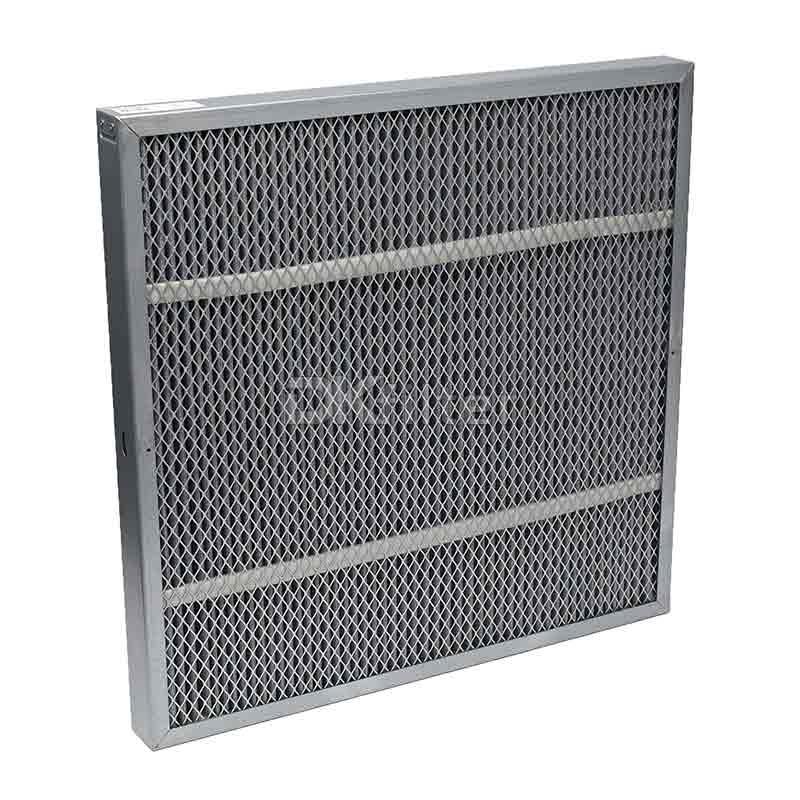

P31058-3 Brief Introduction:

DKFILTER makes kinds of air filter element,when we produce the P31058-3,before filling the filter material,stick a layer of galvanized iron mesh (or stainless steel mesh) on the air outlet surface of the filter material,and then cover with a layer of galvanized iron mesh (or stainless steel mesh) after filling the filter material.The iron mesh can not only protect the filter material from being blown,but also prevent the filter material from being deformed due to wind pressure,so it can ensure that all the filter material surfaces can be fully utilized.

P31058-3 Product Features:

1. Low resistance

2. Large dust holding capacity

3. Large ventilation

4. Detachable

Filter Material:

We make P31058-3 air filter cartridge use a single unit structure to reduce the number of gaskets and improve overall reliability. P31058-3 air cartridge filter have one or more layers of pleated media inside molded fiberglass laminated cylinders to provide a larger particle filtration surface area. Use pleated ripples and separate materials to keep the pleats open for full use.

• The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores.

• All glassfiber media aggregator combines deep particle filtration with deep coalescence structure.

• The all-glass fiber design has a continuous thinner dielectric layer to achieve deep filtration of particles.

P31058-3 Plate air filter Filtration principle:

Interception:

Dust particles in the air move with the airflow in inertial motion or irregular Brownian motion or under the action of some field force.When the particle motion hits other objects,the van der Waals force existing between objects (which is molecules and molecules,molecules The force between clusters and molecular clusters) makes the particles stick to the fiber surface.The dust entering the filter medium has more chances to hit the medium, and if it hits the medium,it will be stuck. Smaller dust collides with each other and will bond with each other to form larger particles and settle down.The particle concentration of dust in the air is relatively stable. It would be a mistake to treat fiber filters like sieves.

Inertia and Diffusion:

Particle dust moves inertially in the airflow.When encountering disorderly arranged fibers,the airflow changes direction,and the particles deviate from the direction due to inertia and hit the fiber and are bonded.The larger the particle and the easier it is to hit, the better the effect.Small particles of dust make irregular Brownian motion.The smaller the particles,the more violent the irregular movement,the more chances of hitting obstacles,and the better the filtering effect. Particles smaller than 0.1 micron in the air mainly perform Brownian motion, the particles are small,and the filtering effect is good.Particles larger than 0.3 microns mainly do inertial motion,and the larger the particle,the higher the efficiency.

P31058-3 Applications:

Used in automotive, food, pharmaceutical,electronics and other industries.It can be used as pre-filter for air-conditioning system,dust-free workshop and clean workshop.

1. Large air compressor pre-filter.

2. Pre-filtration of local high-efficiency filtration devices.

3. Central air-conditioning and centralized ventilation system pre-filtration.

5. Clean return air system.

P31058-3 Detachable Air Intake Panel Hepa Air Filter for Eng

P31058-3 Detachable Air Intake Panel Hepa Air Filter for Eng

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)