Introduction:

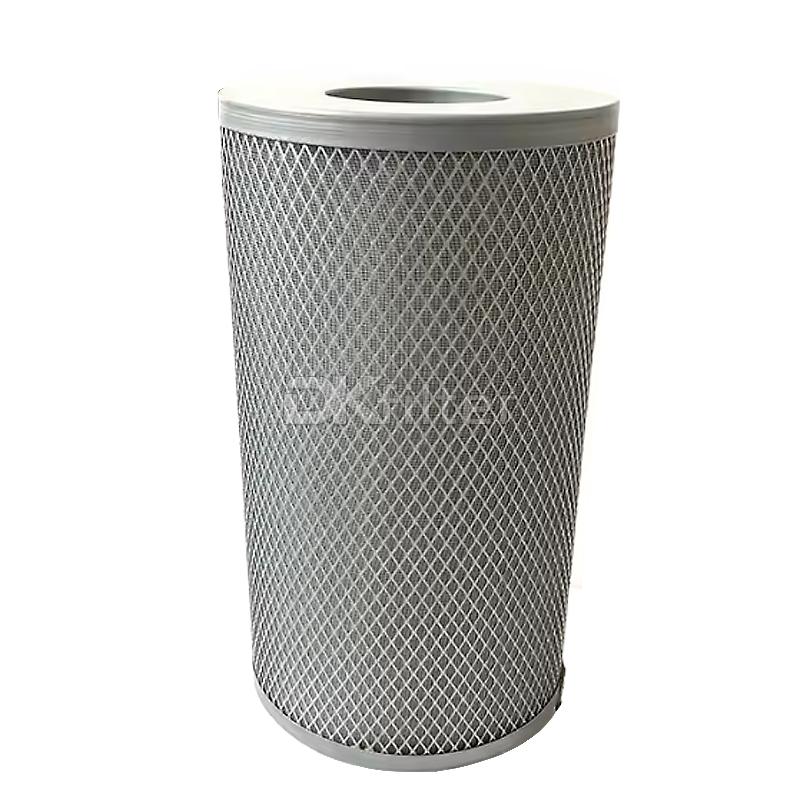

P3515A958 air compressor oil separator is used in air compressors to filter, intercept and remove water, oil vapor and other pollutants and impurities in compressed air pipelines. Separates oil and air to produce high-quality clean, contaminant-free compressed air.

P3515A958 air compressor oil separator manufacturing material is made of anti-corrosion and high-efficiency condensation ultra-fine glass fiber material, which has a long service life and ensures filtration effect. It is an efficient and important mechanical core component of the air compressor filter element coalescing filter.

Technical Datas:

• Filtration precision: 10μm

• Filtration efficiency: 99.8%

• Initial pressure difference: ≤0.02MPa

• Maximum working temperature: 120ºC

• The service life can reach about 3500h-5000h

• The oil content of compressed air can reach less than 3ppm

Filter Material:

We make P3515A958 air oil compressor filter cartridge use a single unit structure to reduce the number of gaskets and improve overall reliability. P3515A958 air cartridge filter have one or more layers of pleated media inside molded fiberglass laminated cylinders to provide a larger particle filtration surface area. Use pleated ripples and separate materials to keep the pleats open for full use.

• The composite glass fiber and fold medium coalescers mainly remove particles from high surface area fold cores.

• All glassfiber media aggregator combines deep particle filtration with deep coalescence structure.

• The all-glass fiber design has a continuous thinner dielectric layer to achieve deep filtration of particles.

Performance Characteristics:

• The use of multi-layer composite filter materials can quickly and efficiently separate oil mist from the air and reduce the oil content.

• The separation efficiency is as high as 99.9%, ensuring that the discharged air meets environmental standards.

• Suitable for various brands and types of air compressors, easy to install and replace.

• Using high temperature resistant materials, it can maintain excellent performance even in extreme environments.

Notes:

Under normal circumstances, P3515A958 is recommended that you replace the filter element every 2000 to 3000 hours. This is because during this period of time, the filter element may become clogged, resulting in a decrease in filtering effect.

Test Standards:

Before delivery, Our manufactured P3515A958 high-efficiency air filter cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent compressor air cartridge filter manufacturer

Parker & Velcon

PECO & Facet

Faudi

Pall

Other types are available on request

P3515A958 Screw Air Compressor Oil Mist Separator Filter

P3515A958 Screw Air Compressor Oil Mist Separator Filter

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)