11427474 Brief Introduction:

The oil air separation filter element 11427474 is a key component that determines the compressed air quality of the air compressor.A good quality oil air separation element can not only ensure the working efficiency of the compressor,but also the life of the filter element can reach thousands of hours.DKFILTER can customize the filter element for you according to the size,picture or drawing provided.

Performance Features:

• Service life:3500-5200h

• Initial pressure difference:≤0.02Mpa

• Filter material:HV or Lydall glass fiber

• Accuracy:can be controlled below 0.1um

• Filter element form:Pleated filter element with 98% filtration efficiency

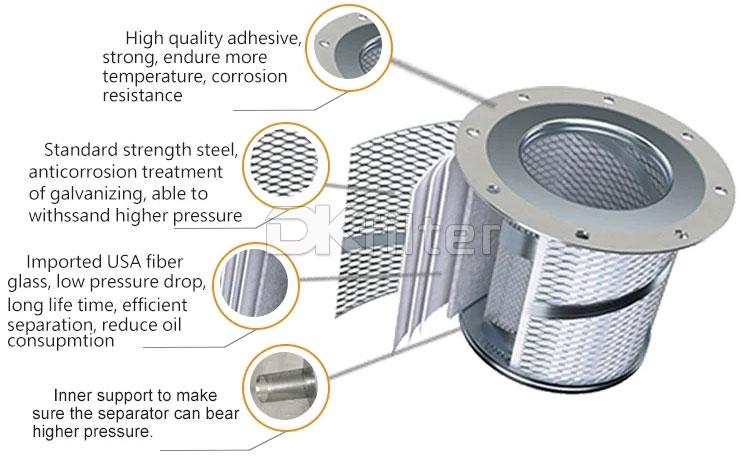

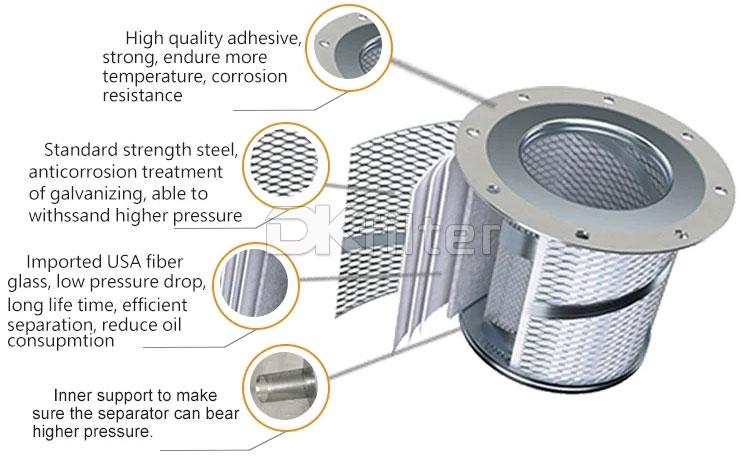

Filter Structrue:

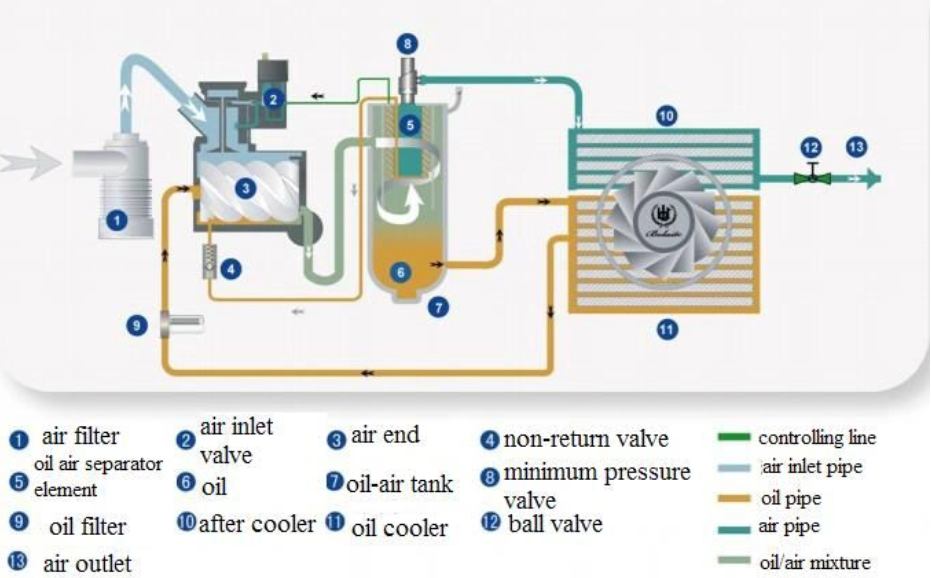

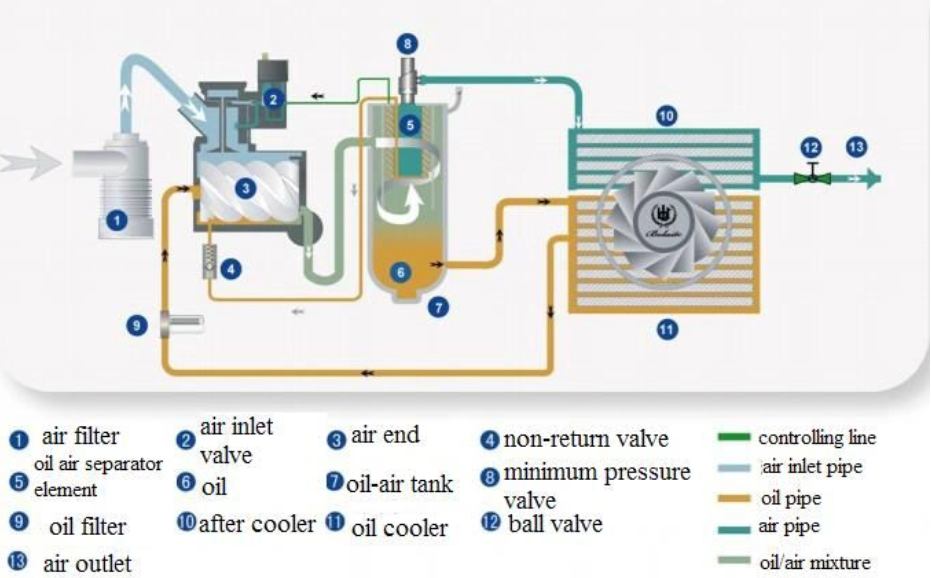

Compair oil separation filter element oil separation 11427474 is mainly installed on the Compair screw air compressor for oil and gas separation.It is an air compressor filter element produced and designed with imported filter materials.The oil air separation element is a key component that determines the compressed air quality of the air compressor.High quality oil air separation elements can not only ensure the high efficiency operation of the compressor,but also the life of the filter element can reach thousands of hours.The compressed air coming out of the compressor head entrains large and small oil droplets.Large oil droplets are easy to separate when passing through the oil-gas separation tank,while small oil droplets (suspended oil particles with a diameter below 1um) must be filtered through the micron and glass fiber filter layer of the oil-gas separation filter element.

Filtration Curve:

The diffusion of oil particles through the filter material is directly intercepted by the filter material and the mechanism of inertial collision and condensation makes the suspended oil particles in the compressed air quickly condense into large oil droplets. Under the action of gravity,the oil accumulates at the bottom of the oil separation core and passes through the bottom.The inlet of the oil return pipe in the recess returns to the lubricating oil system of the machine head,so that the compressor discharges more pure and oil-free compressed air.

We make 11427474 air oil separator filter is Beta grade. Excellent filtration performance. The Beta X = 1000 number means that for every 1000 particles of size x in the fluid, on average only one particle will pass through the filter.

Notes:

The solid particles in the compressed air stay in the filter layer when they pass through the oil separator core,which causes the pressure difference (resistance) of the oil separator core to increase continuously.As the service time of the oil separator core increases,when the pressure difference of the oil separator core reaches 0.08 to 0.1Mpa, the filter element must be replaced,otherwise the operating cost (power consumption) of the compressor will be increased.

Application:

Used in air compressors to extract oil droplets in the compressed air to make the compressed air cleaner. After the oil is extracted, it can continue to be recycled.

Test Standards:

Before delivery, Our manufactured 11427474 air oil separator element will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent oil air separator filter cartridge manufacturer

ATLAS COPCO Filters

INGERSOLL RAND Filters

SULLAIR Filters

COMPAIR Filters

FUSHENG Filters

LIU-TECH Filters

MANN Filters

Hitachi Filters

Kaeser Filters

Other types are available on request

11427474 Compair Oil Air Separation Filter Element

11427474 Compair Oil Air Separation Filter Element

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)