Introduction:

2901-0566-22 oil mist separator filter element is used to remove solid dust, oil and gas particles and other liquid substances in compressed air. The main function is to enter the oil-containing compressed air generated by the host into the cooler, enter the oil and gas filter element for filtration through mechanical separation, intercept and aggregate the oil mist in the gas, and form oil droplets concentrated at the bottom of the filter element, and return to the compressor lubrication system through the oil return pipe , so that the compressor discharges clean, high-quality compressed air.

Performance Parameters:

| Item | Value |

|---|

| Filtration accuracy..... | 10 μm |

| Filration Rate.... | 10 Micron |

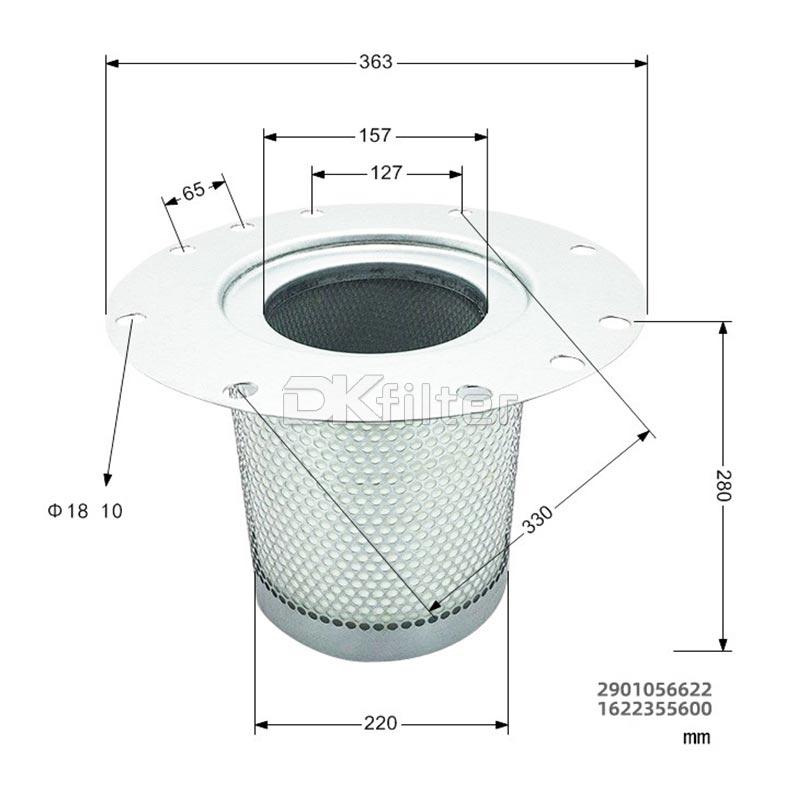

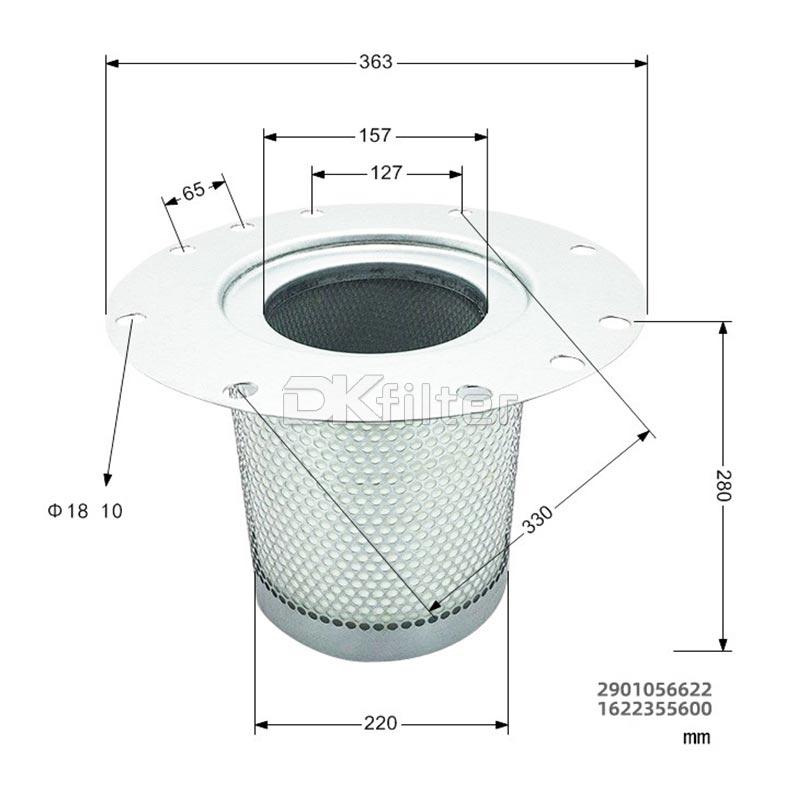

| Sizes | OD8.58"*L10.87"..... |

| Seal | Viton |

| Thread | 1" x 12 UNF |

| Product Net Weight......... | 4.32Kg |

| Gasket | Buna O-Ring |

| Filter material.... | Fiberglass..... |

| Center Tube | Corrosion Resistant Steel.... |

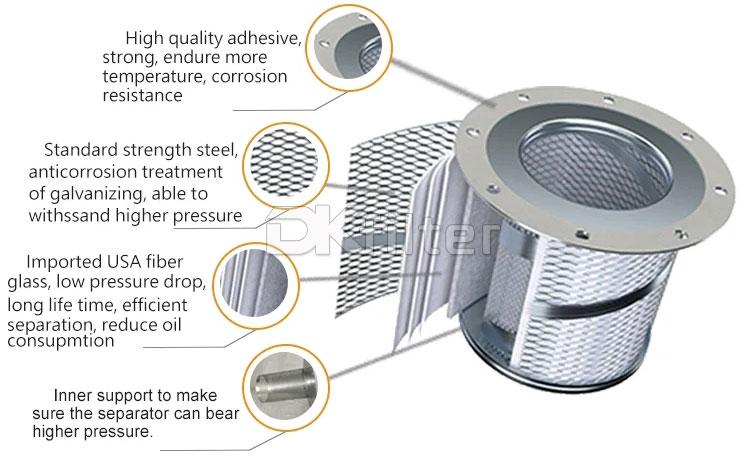

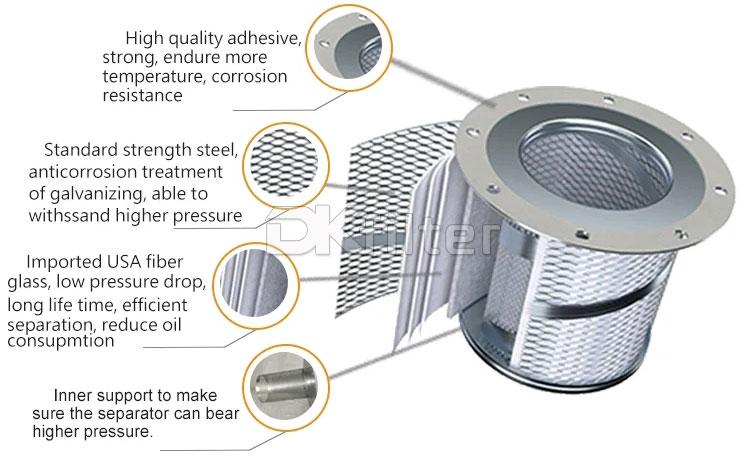

Filter Structrue:

Our manufactured 2901-0566-22 air oil separator for rotary screw and vane air compressors provide ultimate filtration with 0.3 micron rating.All particles larger than 0.3 microns that pass through the air and oil filters will be trapped by the separator.The separator is composed of deep loading medium and has good fouling capacity.

The basic purpose of 2901-0566-22 air compressor oil filter is to separate oil from air through coalescence. The oil is physically trapped by the separator while allowing air to pass through. The oil is then drained to the oil pan, removed through the collection line and returned to the oil pan, and returned to the oil pan for continuous cycle recompression.

Performance Features:

1. 2901-0566-22 compressor oil separator is made of ultra-fine glass fiber composite filter material from HV Company and Lydall Company of the United States.

2. The mist oil and gas in the compressed air can be almost completely filtered out when it passes through the oil separator.

3. Compressed air oil mist particles can be controlled below 0.1μm,and the oil content of compressed air can be controlled within 3~6PPm.

4. The service life of the oil separation core is 3500~5200h,and the quality of lubricating oil and the environment have a great impact on its service life.

5. Initial pressure difference: ≤0.02Mpa.

Test Standards:

Before delivery, Our manufactured 2901-0566-22 compressor oil separator cartridge will be tested and follow the standards:

ISO 2941 Collapse & Burst Resistant

ISO 2942 Fabrication & Integrity Test

ISO 2943 Material Compatibility with Fluids

ISO 3724 Flow Fatigue Characteristics

ISO 3968 Pressure Drop vs. Flow Rate

ISO 16889 Multi-pass Performance Testing

Customized Processing:

We corporation are excellent separator cartridge filter manufacturer

ATLAS COPCO Filters

INGERSOLL RAND Filters

SULLAIR Filters

COMPAIR Filters

FUSHENG Filters

LIU-TECH Filters

MANN Filters

Other types are available on request

2901-0566-22 oil separator for Atlas GA75 screw compressor

2901-0566-22 oil separator for Atlas GA75 screw compressor

General specifications

General specifications

![[field:title/]](/p0228/Images/wz.png)